Ever felt bogged down by complex ISO code when programming your CNC surface grinding machine?

The ALPA System Touch with Fanuc CNC is here to streamline the process for your surface grinder. This innovative system utilizes a user-friendly interface that replaces intricate code with straightforward prompts and tables, making programming faster and more accessible.

Key Features of the ALPA System Touch

- Fanuc-based Operating System: Leverages the reliability and familiarity of the industry-standard Fanuc system.

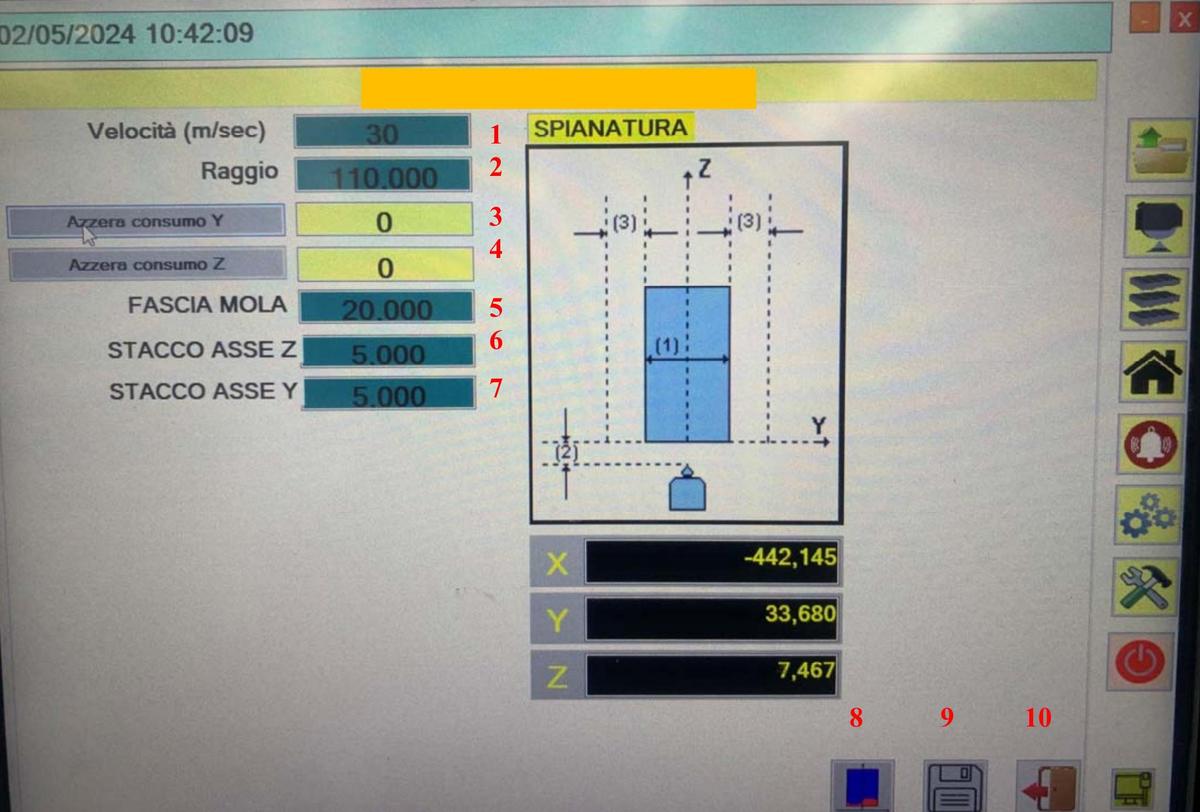

- Simplified Programming: Operator interfaces designed for ease of use, allowing you to program through intuitive menus instead of writing extensive ISO code.

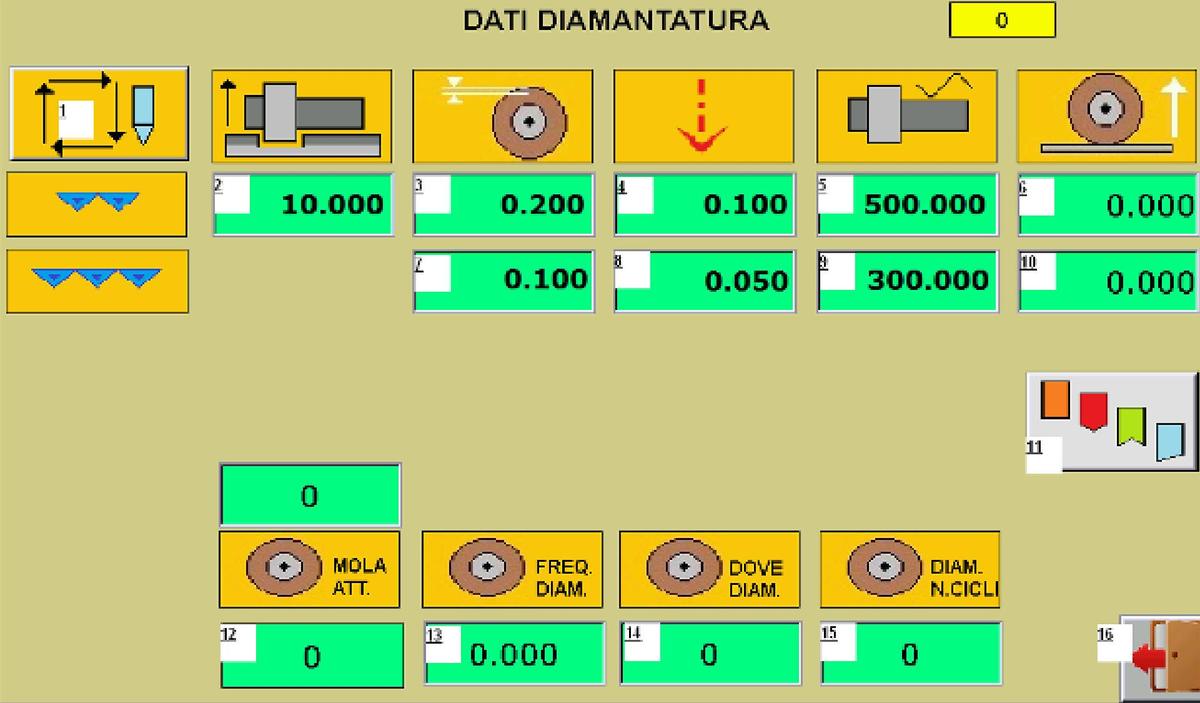

- Pre-defined Cycles: Streamline common machining tasks with built-in cycles for roughing, finishing, flaming-stopping, flattening, plunging, and more. These cycles can even be chained together for multi-level machining.

- Automatic Features:

- Linear Dressing: Ensures consistent tool performance with automatic wheel maintenance.

- Wheel Consumption Compensation: Automatically adjusts for wheel wear, maintaining machining accuracy.

- Flexible Machining:

- Floor Finishing: Dedicated cycle for precise finishing of flat surfaces.

- Multi-Axis Capability: The underlying Fanuc 0iMF system allows for expansion up to 6 axes, enabling profile machining and complex operations.

- Tool Memory: Stores and recalls wheel origins and consumption data for efficient tool management.

- Customizable Solutions: For high-production environments, ALPA offers the option to create custom work cycles tailored to your specific needs.

- Industry 4.0 Ready: Future-proof your machine with optional Industry 4.0 compatibility, allowing for integration with advanced automation systems.

Overall, the ALPA System Touch with Fanuc CNC is a powerful solution for both experienced machinists and those new to CNC programming. With its user-friendly interface, pre-defined cycles, and automatic features, it simplifies programming tasks, reduces errors, and improves overall machining efficiency.