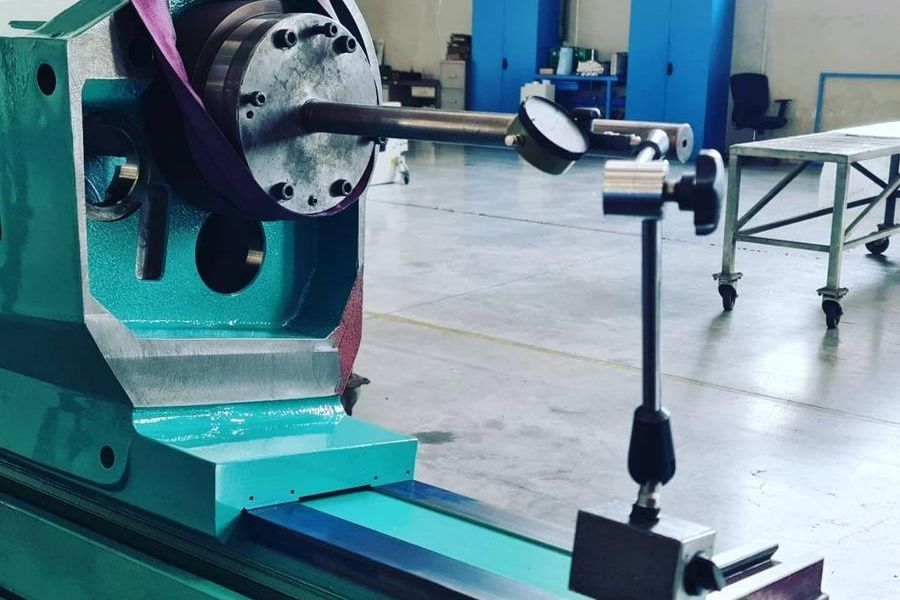

Our Crankshaft grinders by Robbi are used for grinding journals and crank pins to remove material and refurbish this vital engine part and expensive-to-replace unit. Usually done when rebuilding an engine, crankshaft grinding also improves engine performance.

In every high-functioning engine is a finely crafted crankshaft. Through the connecting rods, the crankshaft transfers power from the piston movement from linear to rotational. This harnessed power is used by most conventional cars, diesel marine engines, locomotive internal combustion engines, large compressors, and other heavy-duty machinery.

Our crankshaft grinders are suitable for single-piece runs and for production lots.

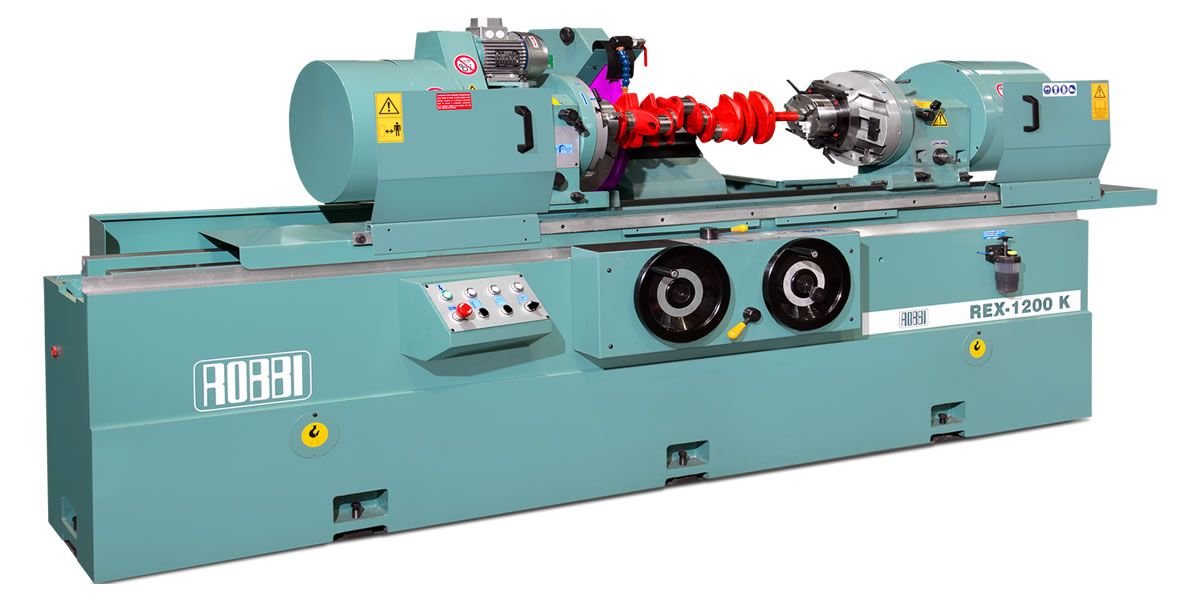

Robbi Crankshaft Grinders

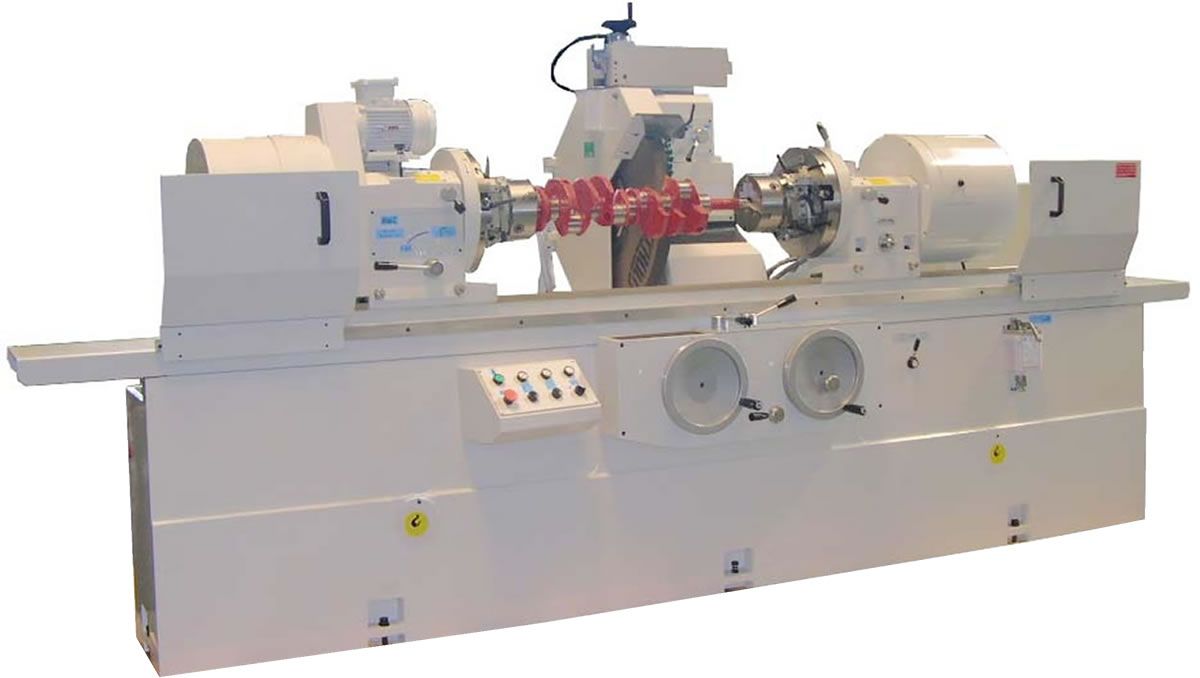

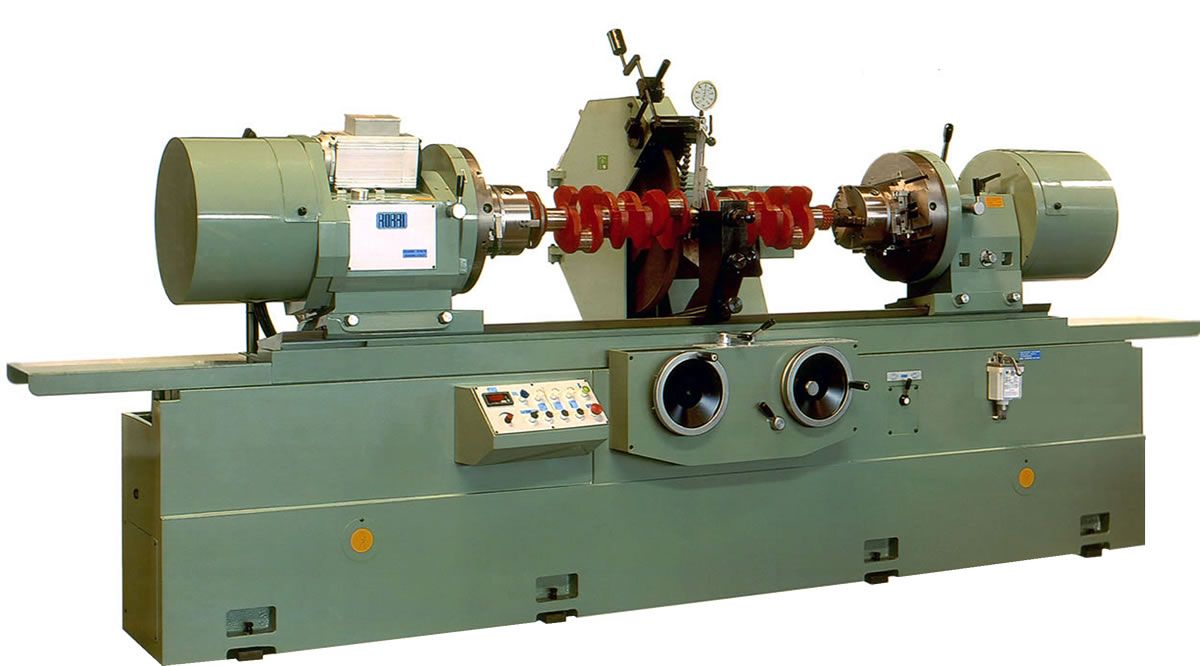

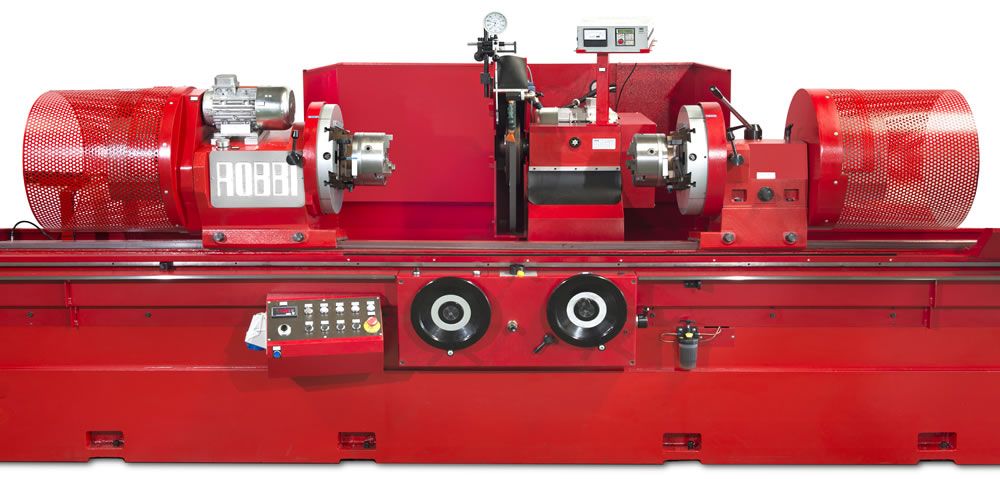

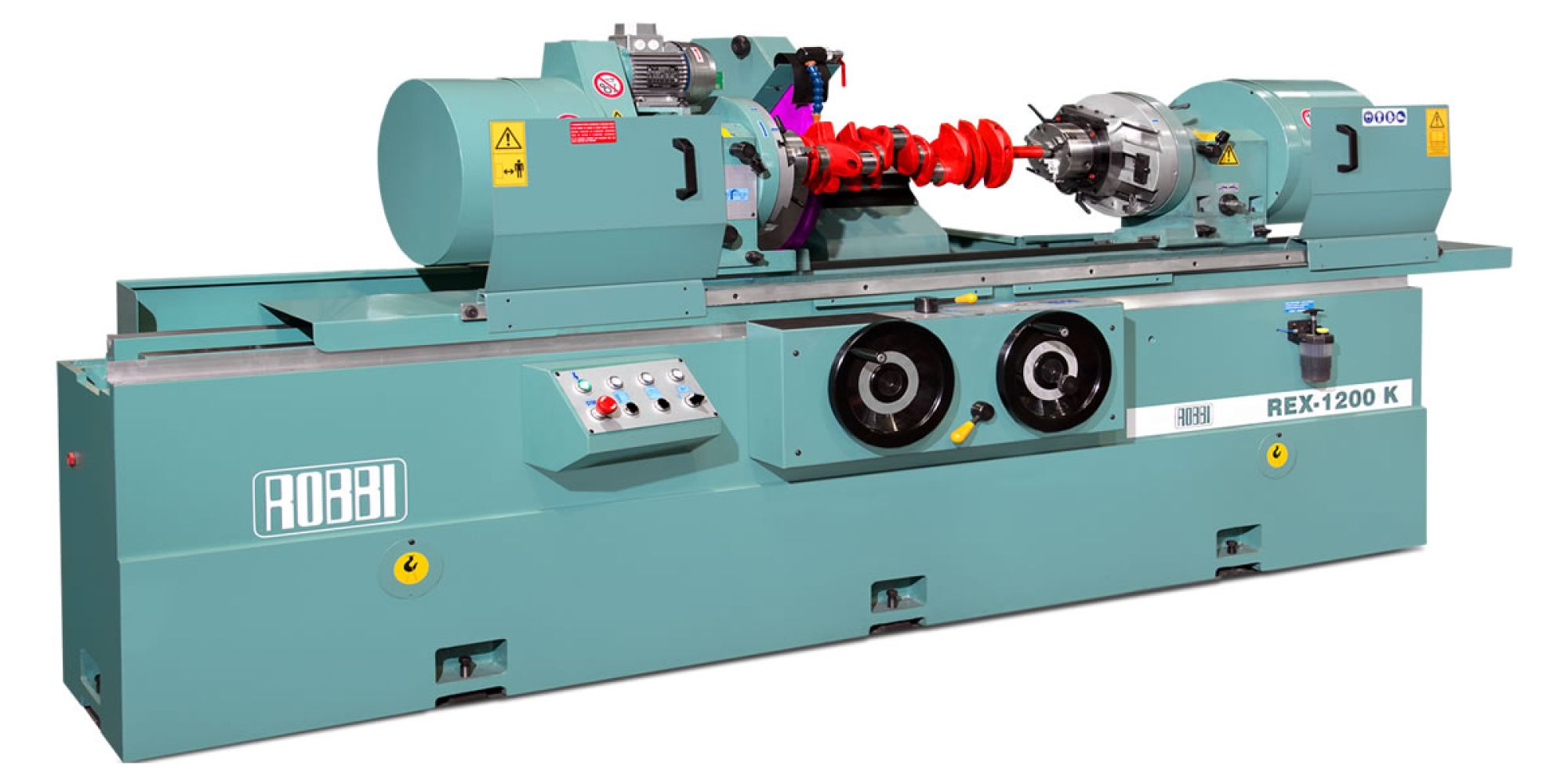

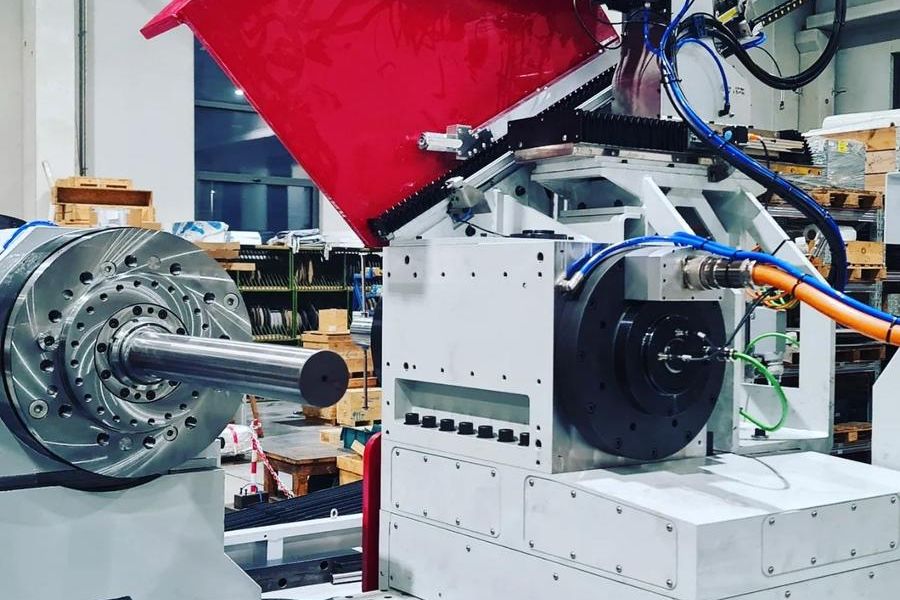

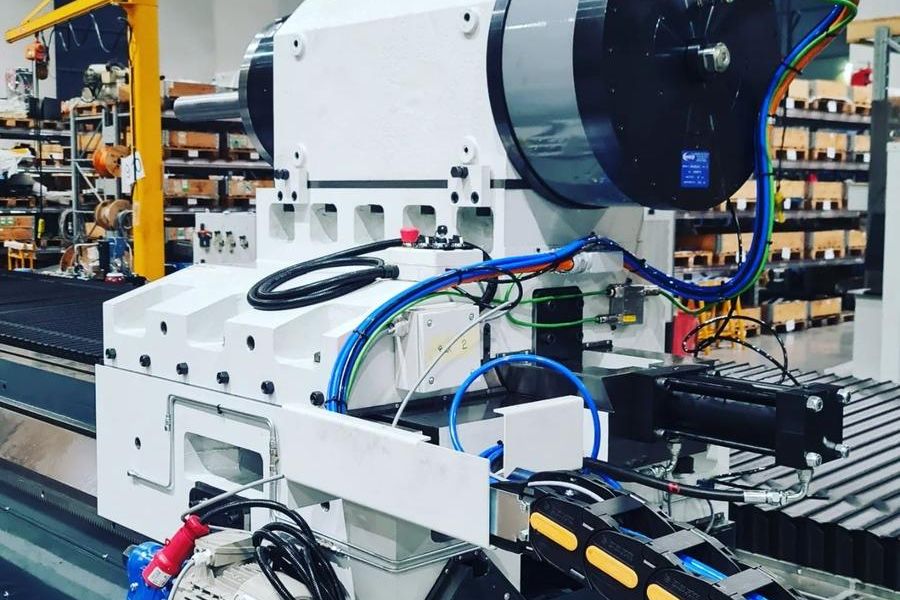

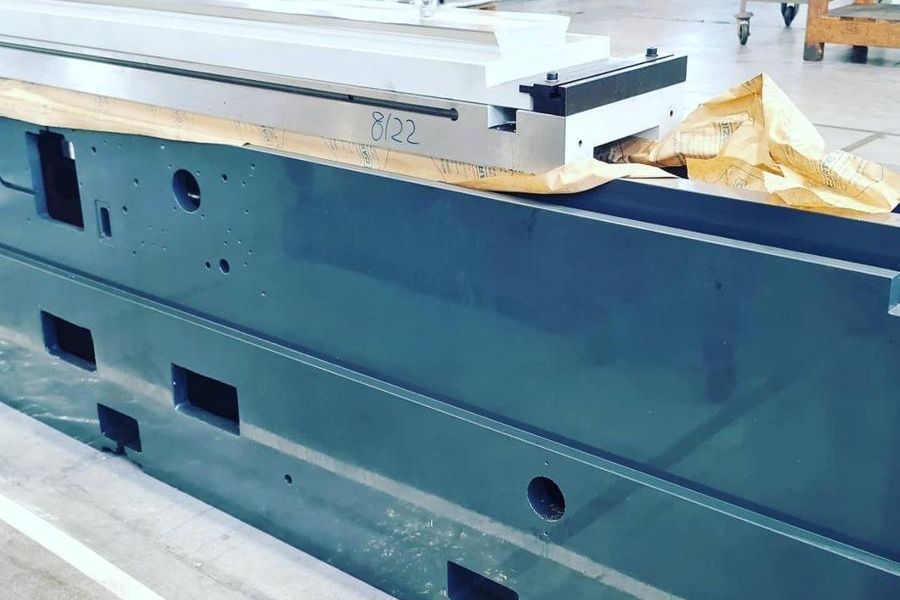

Robbi offers a line of crankshaft grinders that includes their heavy-duty industrial line. These machines are designed for high accuracy and efficient operations using workheads with 4-way cross-slides and an advanced locking system for quick crankshaft centering.

With lifetime superior accuracy and dependability, these one-piece cast iron constructed machines also deliver various configurable options to make the machine tool work best for how you need it.

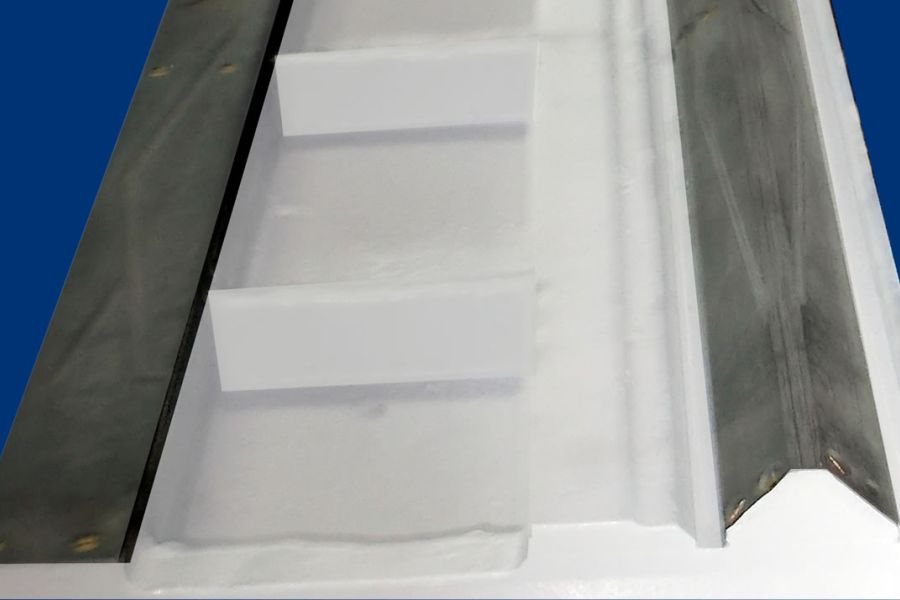

- Wheel Head: The wheel head is coated with anti-friction material and bathed in adjustable bearings to allow free movement and minimize wear on the machine

- Hydraulic Controls: Increase setup and grinding speed with the rapid hydraulic wheel head and table.

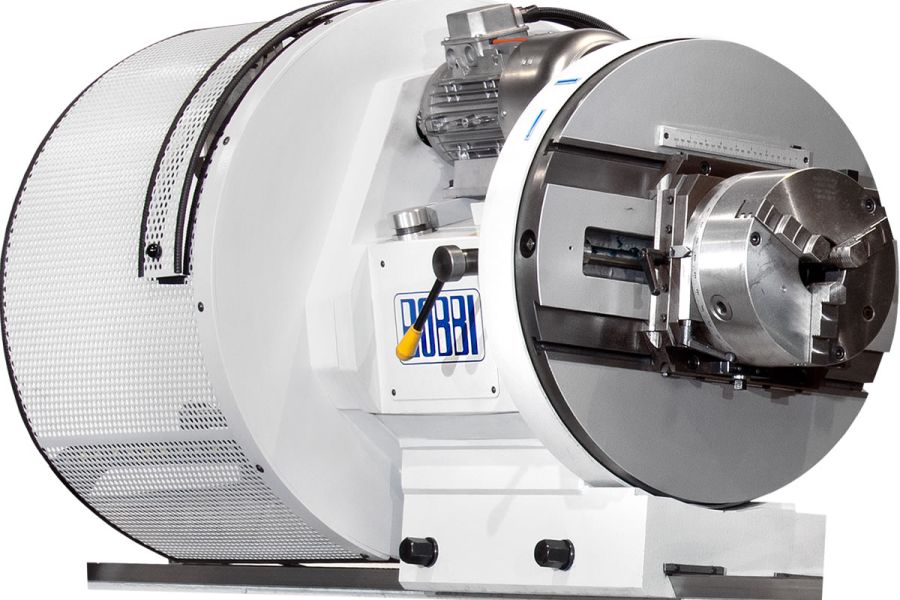

- Work Heads: With only two keys for all shifting, centering, and clamping operations indexed chucks easily change from chucks to centers and rotate 360 degrees.

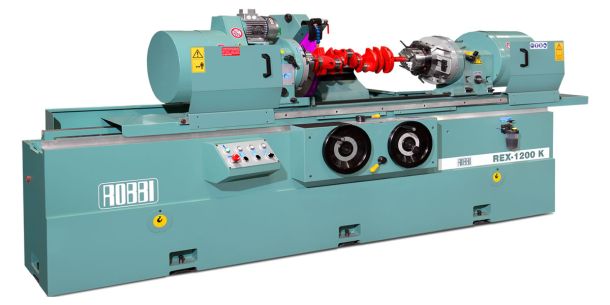

Standard Line of Crankshaft Grinders

Ecotech Machine Tool offers four convention crankshaft grinding machines.

Industrial Line of Crankshaft Grinding Machines

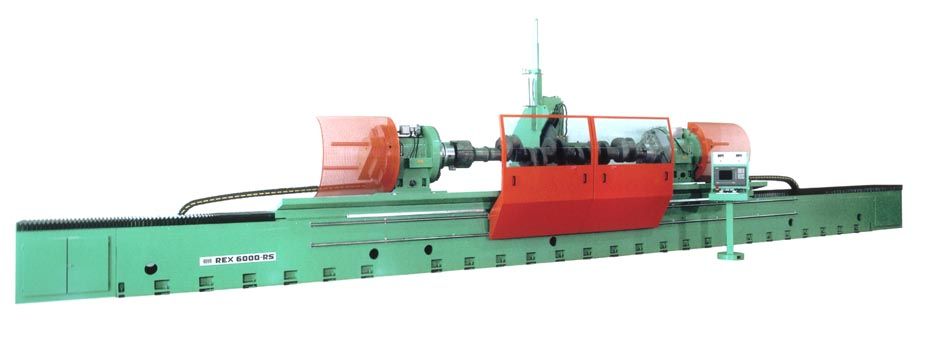

We also offer four industrial line machines, with an option for CNC in the Rex 400 machine model.

Movie

General Information

-

Machine Types

Conventional & CNC (Rex 4000)

-

Models

Conventional: Rex 1,200-6,000

CNC: Rex 4,000-12,000 -

Distance Between Centers

1320mm - 6000mm

-

Grinding Diameter

180mm-500mm

-

Manufacturer

The Robbi Group

About The Robbi Group

Robbi is an industrial machine manufacturer based out of Italy and since 1936. Robbi uses materials and high-quality components to deliver the utmost precision. Most of their mechanical components are created in their machine shop.

Their company mission is to design and manufacture precision machine tools, technologically advanced, reliable, safe, easy to use, and “tailor-made” for each customer.

Why Buy A Robbi Crankshaft Grinder?

-

Unmatched Precision: Our crankshaft grinders offer lifetime superior accuracy and dependability, ensuring top-notch performance.

-

Efficient Operations: Equipped with workheads featuring 4-way cross-slides and an advanced locking system, our machines center and grind crankshafts quickly.

-

Tailor-Made Options: Configurable settings allow you to customize the machine to your specific needs for the best results.

Machine Model Technical Comparison Chart

| Model | Distance Between Centers | Height of Centers Over Table | |

|---|---|---|---|

Rex 1200 | 1230mm | 220mm |

|

Rex 1500 | 1550mm | 250mm |

|

Rex 1800 | 1800mm | 300mm |

|

Rex 1800 RM | 1800mm | 350mm |

|

Rex 2200 L | 2300mm | 300mm |

|

Rex 2200 RM | 2300mm | 350mm |

|

Rex 3100 | 32000mm | 400mm | |

Rex 4000 CNC | 4200mm | 650mm | |

Rex 6000 | 6000mm | 750mm |