Robbi Internal Grinders (ID) — CNC & PLC

These internal grinding machines offer excellent versatility, high levels of quality, batch size flexibility, easy workpiece presetting, and effective complex component processing.

Internal grinding is an abrasive form of machining that uses a rough grinding wheel to cut through a variety of hard materials. This machine is a great option for grinding the internal diameter of a workpiece.

All of our Internal Grinders have heavy aged cast iron construction precisely machined and scraped by hand. Expect many years of problem-free operations and high accuracy due to the Hydro-Static lubrication system on the table.

Omicron IGR — PLC or CNC

With excellent versatility and high-quality standards, the IGR 250 and 600 provide small batch production of workpieces in manual or semi-automatic modes. You can even craft a single workpiece.

On machine-setup, the workpiece presetting is configured and then you're set to produce. Produce quickly and precisely, even when dealing with complex components, and take advantage of more sophisticated functions with machine upgrades.

Omicron IGU CNC

If your production is seeking high precision grinding, the CNC IGU 400 is the machine you're looking for. With up to 4 grinding spindles on the rotating turret, this CNC motor-controlled machine and software interpolation 2-axis allow various ray adjustments, customized to your production requirements. Also, tap into roller linear guides (for maximum rigidity), a granite base (low thermal expansion), an incremental linear encoder (dampens vibrations), and axis movement via the high precision re-circulating ball screw.

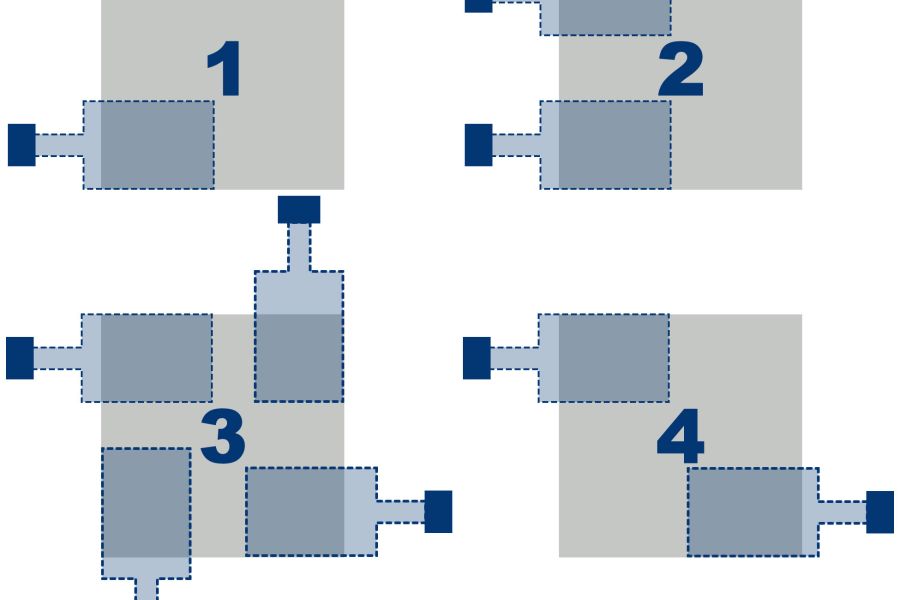

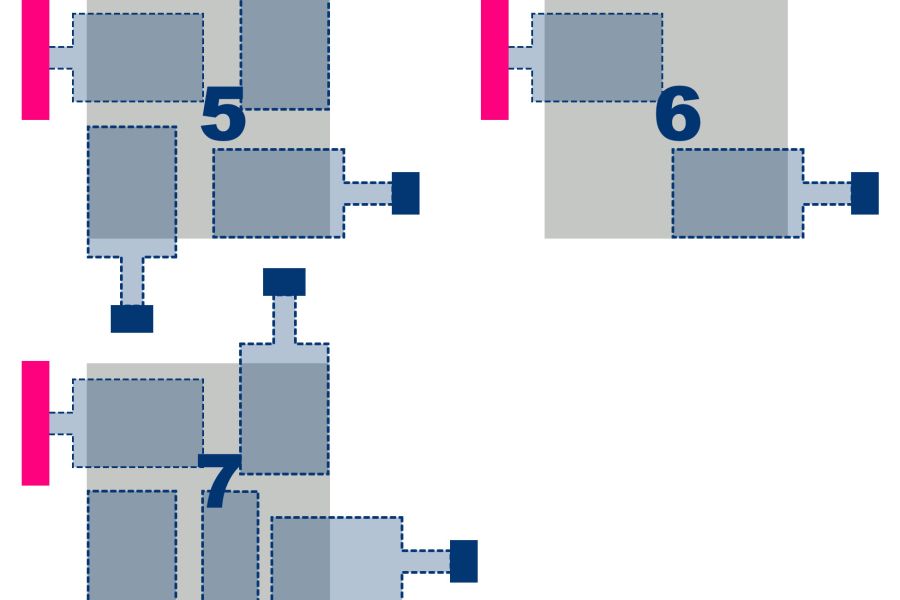

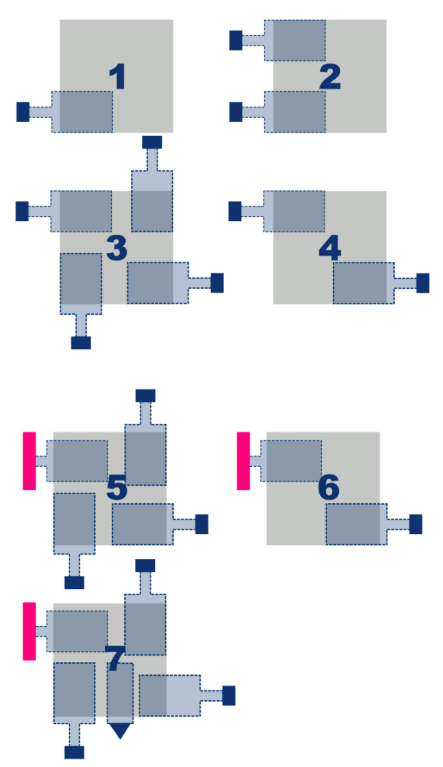

Up to 4 Grinding Spindles on Rotating Turret

The IGU 400 Internal Grinding Machine offers a versatile spindle turret configuration. In its maximum configuration, the turret can accommodate:

- 4 spindles: One for external grinding and three for internal grinding.

- Tailstock: To accurately center the grinding bore.

- Integrated swivel axis: Enables automatic operation of up to four grinding spindles.

The turret rotates automatically and positions precisely. However, versions 1 and 2 do not have a rotating turret.

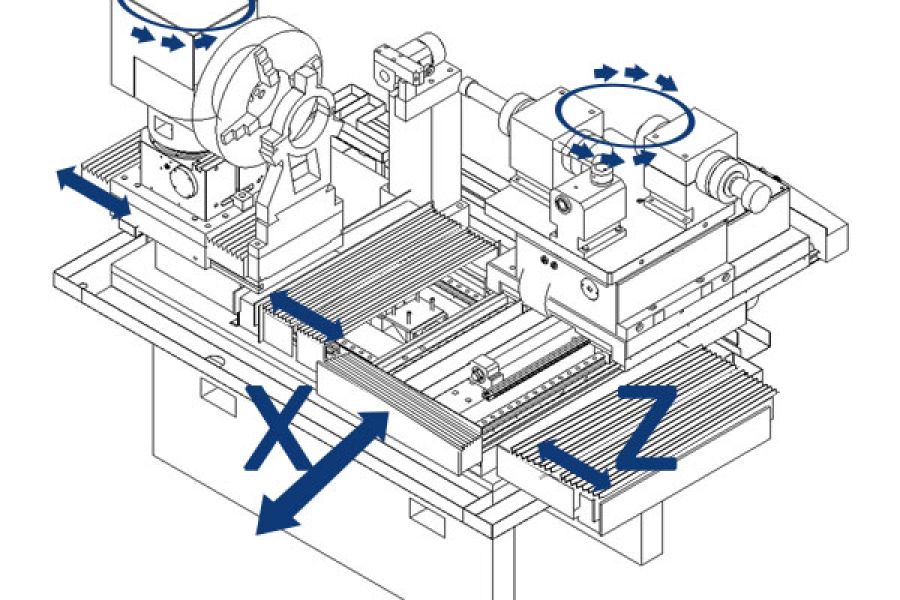

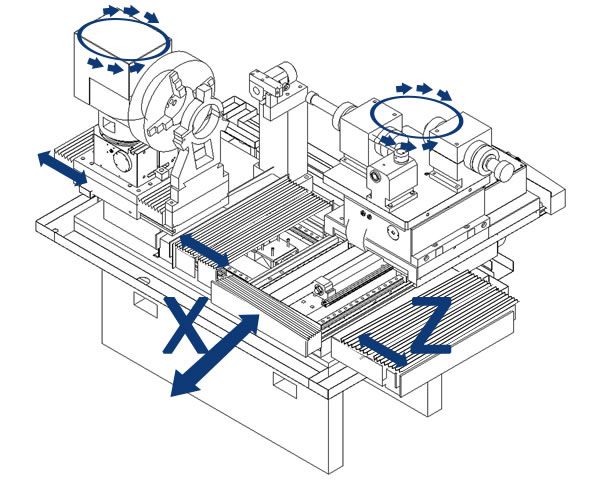

Flexible X and Z Axis

Granite Base

- Low thermal expansion

- Excellent rigidity

- Absorption of the vibrations

Roller Linear Guides

- Maximum rigidity

- Speed and acceleration over the very low speed

- Elimination of stick-slip.

Incremental Linear Encoder on Both Axis

- Small coefficients of variation.

- Dampens vibrations optimally.

- No vibration side

- Maximum positioning accuracy and repeatability

- Excellent performance during the working in interpolation

High Precision Re-Circulating Ball Screws

Machine Model Technical Comparison Chart

| Model | Height of Centres Over Table | Workhead Rotation Speed | |

|---|---|---|---|

IGR 250 | 180/230 mm | 0-400 RPM |

|

IGR 600 | 180/230 mm | 0-400 RPM |

|

IGU 400 CNC | 325 mm | 0-800 RPM |

|

General Information

-

Machine Types

Semi-Automatic (PLC) & CNC

-

Models

IGR (250 + 600) & IGU

-

Height of Centres Over Table

180mm - 325mm

-

Max. Table Speed

4,000mm/min - 10,000mm/min

-

Manufacturer

The Robbi Group

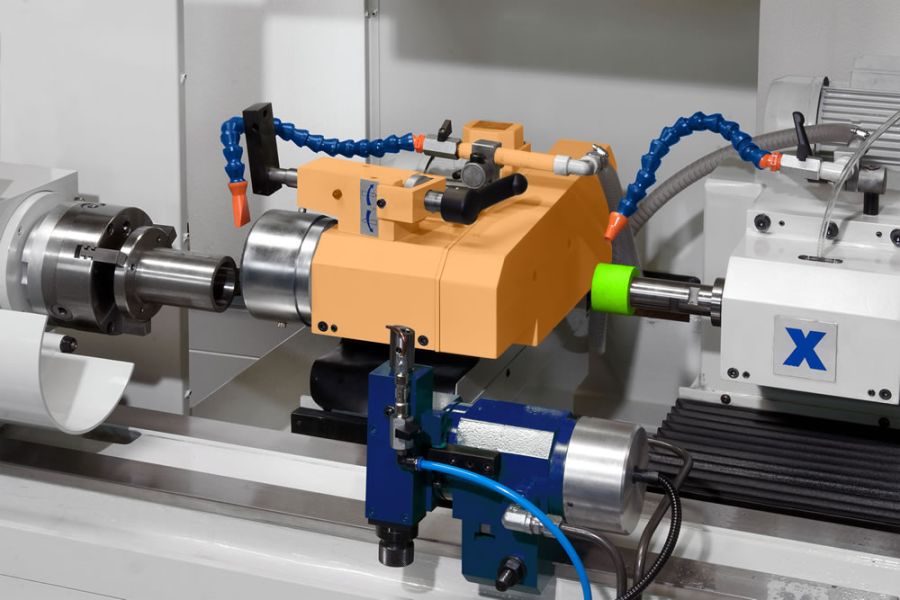

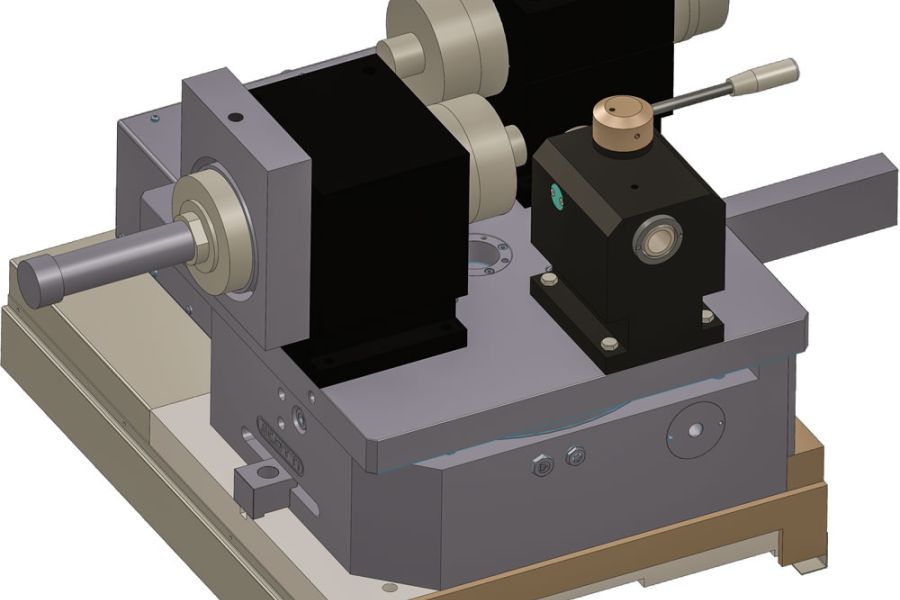

Internal Grinding Components

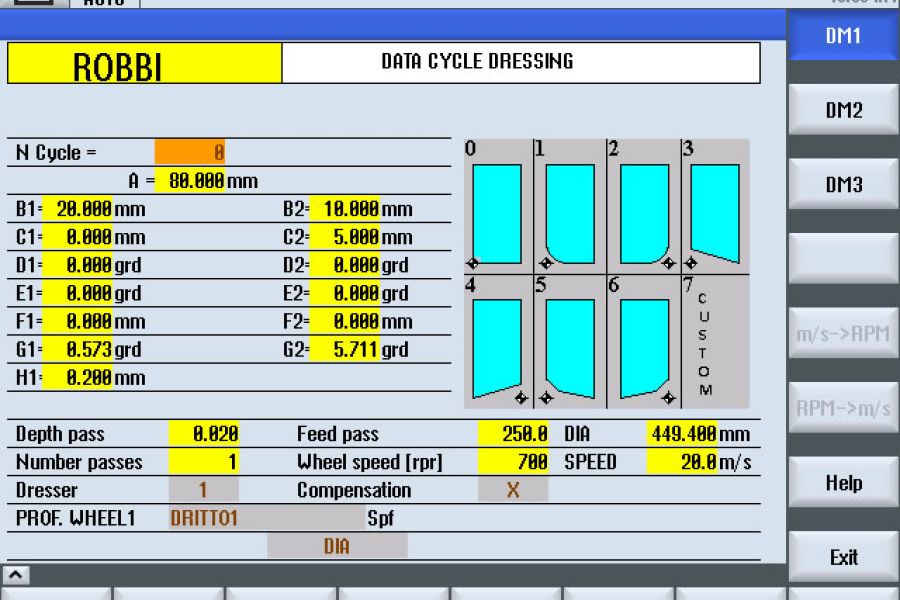

Measures and Control

Grinding Dressing Wheel

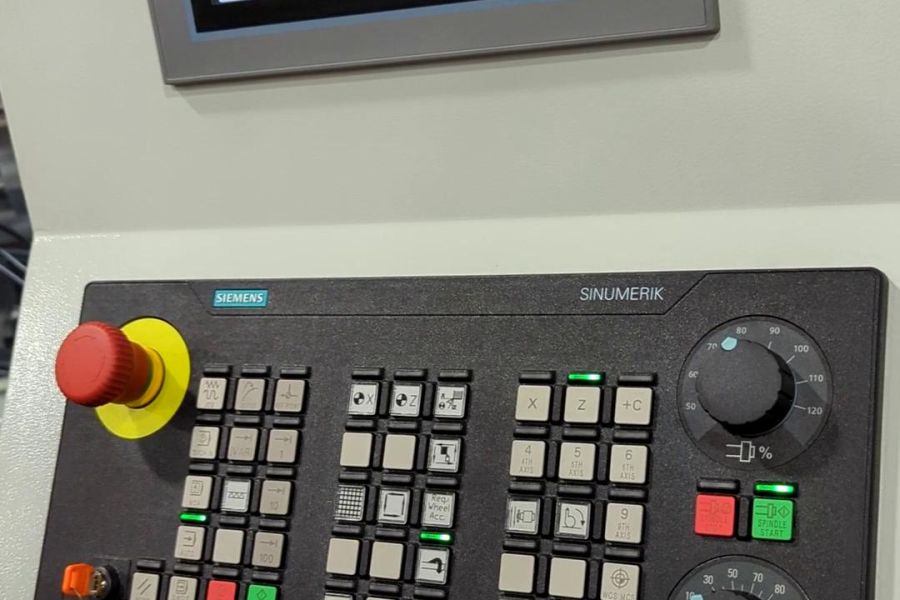

Operator Panel

Tailstock

Wheelhead

Workhead

Internal Grinding Spindle

About The Robbi Group

Robbi is an industrial machine manufacturer based out of Italy and since 1936. Robbi uses materials and high-quality components to deliver the utmost precision. Most of their mechanical components are created in their machine shop.

Their company mission is to design and manufacture precision machine tools, technologically advanced, reliable, safe, easy to use, and “tailor-made” for each customer.

More About The IGR-250 Robbi Internal (ID) Grinder — CNC & PLC

Are you worn out and struggling with your current internal grinding process?

Do you wish for a solution that provides unparalleled precision, efficiency, and control?

Look no further!

Ecotech Machine Tool is thrilled to introduce you to the Robbi Omicron IGR 250, the ultimate internal grinding machine designed to transform your manufacturing operations.

Unlocking a new realm of possibilities, the Robbi Omicron IGR 250 boasts cutting-edge features and state-of-the-art technology. With its Siemens TP 700 touchscreen control, this machine equips operators with a seamless user experience and unmatched control over internal grinding operations.

Key Features of the Robbi Omicron IGR 250:

- Impressive Grinding Capacity: The IGR 250 offers a maximum grinding diameter of 9.80”, allowing you to tackle a wide range of workpieces with ease. Additionally, the optional maximum swing of 17.90” enables you to accommodate larger components without compromising precision or performance.

- Belt-Driven Internal Grinding Spindle: Equipped with a powerful belt-driven internal grinding spindle, the IGR 250 achieves a remarkable 27,000 RPM, ensuring fast and precise grinding results. Say goodbye to time-consuming grinding processes and welcome enhanced productivity into your workshop.

- Siemens TP 700 Touch Screen Control: The intuitive Siemens TP 700 touch screen control system brings a new level of simplicity and efficiency to your operations. Its user-friendly interface allows operators to program and monitor the grinding parameters effortlessly, ensuring precise and consistent results every time.

- Unmatched Precision and Versatility: The Robbi Omicron IGR 250 is engineered to deliver exceptional precision, allowing you to meet the most demanding tolerances and specifications. From small-scale production runs to complex components, this machine is your gateway to unparalleled versatility and top-notch quality.

- Enhanced Safety Features: Your operators' safety is our top priority. The IGR 250 is equipped with advanced safety measures, including protective enclosures, emergency stop buttons, and intelligent fault detection systems. Experience peace of mind as your team operates in a safe and secure environment.

When it comes to internal grinding, the Robbi Omicron IGR 250 is in a league of its own. Whether you're in the automotive, aerospace, or general engineering industry, this machine is tailored to elevate operational grinding capabilities and drive your business forward.

Don't miss out on this game-changing solution!

Contact us today (770-279-2001) to schedule a personalized demonstration of the Robbi Omicron IGR 250. Let us show you how this remarkable machine can transform your internal grinding process and help you stay ahead of the competition.

Precision, efficiency, and control are just a phone call away.

The Robbi IGR 250 internal grinder is a versatile and efficient machine tool designed for precision internal grinding operations.

Its intuitive SIEMENS TP 700 control panel allows for easy programming of grinding cycles, including plunge and pass modes. The machine can handle up to 12 different diameters in a single cycle, and the operator panel provides real-time visualization of wheelhead and table positions.

For added flexibility, manual grinding cycles with diameter-based stops are available. The IGR 250 also supports automatic grinding wheel dressing with compensation for dimensional accuracy.

Optional in-process measuring gauge and gap control systems further enhance the machine's precision and efficiency.

Additional IGR 250 Internal Grinder Technical Specifications

| Machine Technical Specifications | IGR 250 | |

|---|---|---|

Maximum internal grinding diameter capacity | 250 | mm |

Height of centres over table | 180/230 () | mm |

Max cantilever weight (150 mm from workhead spindle nose) | 80 | kg |

Maximum distance between headstock plate and grinding spindle attachment | 1200 | mm |

Maximum diameter of internal grinding spindle | 120 | mm |

Maximum table swivel | +8°-4° | deg |

Table speed | 0-4000 | mm /min |

| Motors | IGR 250 | |

|---|---|---|

Grinding wheel | 4 | kW |

Workhead | 4 | kW |

Hydraulic unit | 0,75 | kW |

| Workhead | IGR 250 | |

|---|---|---|

Rotation speed | 0-400

| rpm |

Internal centre taper | 5 | MT |

Self centering chuck diameter* | 250 | mm |

| Face Grinding Device | IGR 250 | |

|---|---|---|

Maximum grinding diameter | 355 | mm |

Grinding wheel diameter | 125 | mm |

Maximum swivel | 10° | deg |

Grinding wheel motor | 1,1 | kW |