Robbi Cylindrical Grinders — CNC, PLC, & Conventional

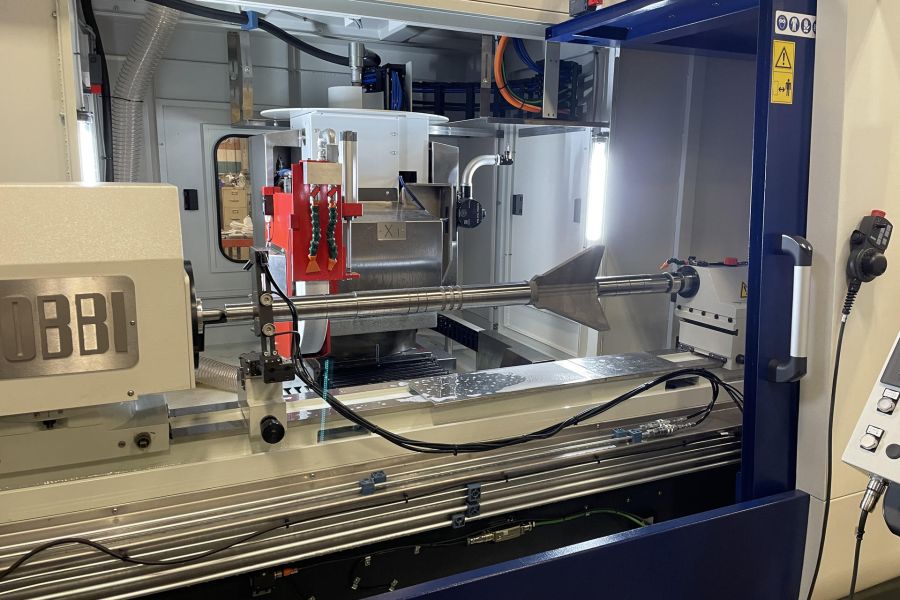

Ecotech Machine Tool's primary universal cylindrical grinding machines are made in Italy by the worldwide leading manufacturer, ROBBI. These machines use high-quality components and an internal workshop produces most of the mechanical components used in the machines.

In-Stock Grinding Machine | Omicron 600 ET7

Our variety (Conventional, PNC, & CNC models) of Robbi cylindrical grinding machines, differing in size and productivity, provides you with a grinding machine uniquely suited for your application.

Degree of Precision

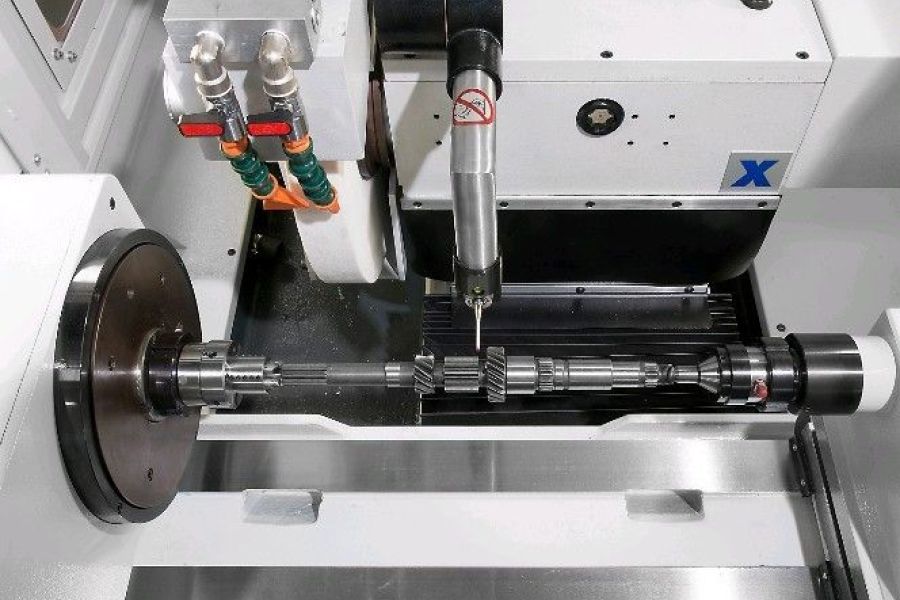

In line with international precision norms (ISO 2433), Robbi CNC grinders have a guaranteed deviation and finish. The table movement linearity is guaranteed by a maximum deviation of 0.0002 mm/m.

- Surface finish degree: Ra 0.2 μ

The obtainable grinding roundness is as follows:

- grinding between centers 0.3 μ

- grinding with live spindle 0.4 μ

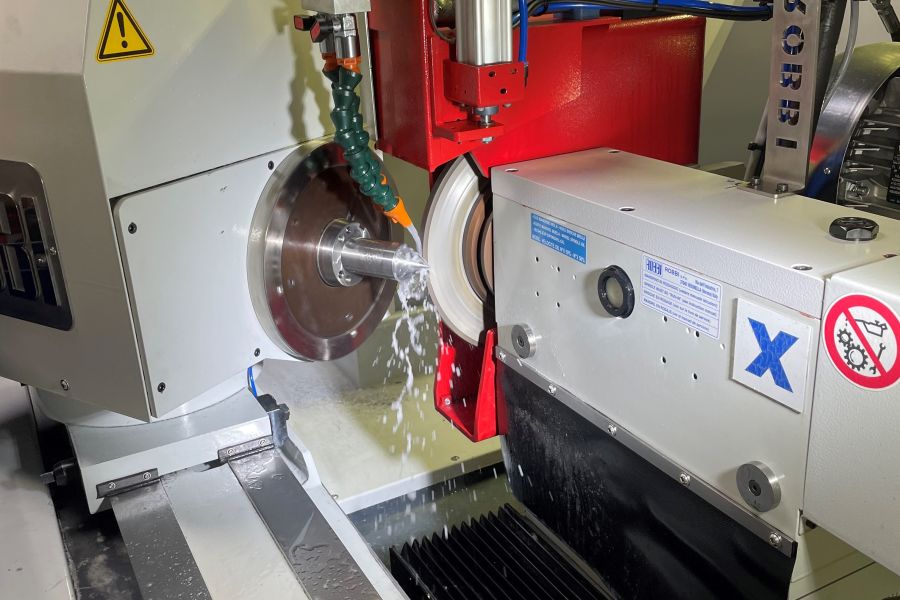

CNC Cylindrical Grinders

To meet the needs of mass production, these reliable Universal CNC grinding machines were created by the Robbi Group. Using only the most advanced mechanical and electronic systems, this embedded software enables complex grinding cycles in a simple and intuitive way without the need for an advanced macro specialization.

- These machines are equipped with the latest generation of the SIEMENS Control System.

- Leverage better angle management with this CNC machine.

- Optionally, add a third interpolated axis.

- Use for high production or small lots.

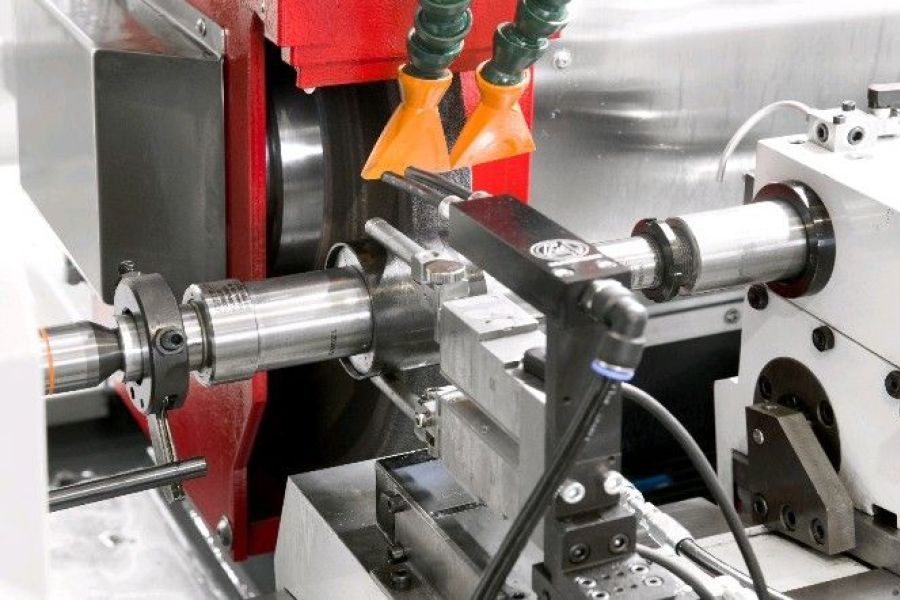

- Automatic measurement devices installed.

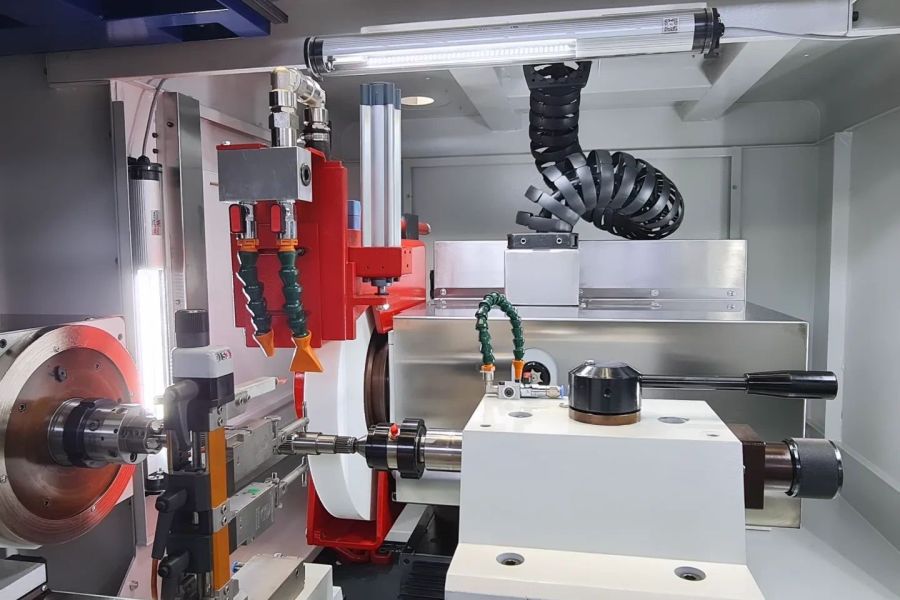

Additional Customization Options

- Controlled continuously or indexed C and B Axes

- Hydrostatic or electric spindle

- Grinding spindle hydrodynamic

- Moving table

- Movile Mola

- Completely closed fairings

- Robot manipulator connections

- Grinding of curved cylinders and respective measuring cycle

- Rubber cylinder grinding

- Non-circular elements and CAMS rectification

- Diamond dresser with CAD program loaded profile

Semi-Automatic Cylindrical Grinders — PLC

With top-level quality standards and a range of versatility, our Robbi semi-automatic machines allow for the matching of individual or series generated parts in manual or automatic modes. The simplified preset grinding wheel piece provides fast and precise machining of complex components thanks to the probes and optional measuring contact.

The semi-automatic grinding machines Robbi are driven by brushless motors with no use of hydraulic movement driven by a ball screw. Multi-scale electronic flyers perform manual micrometric movements delivering constant speed movements, stiffness, and greater positioning accuracy.

And, the programming is simple, intuitive, and provides many easily learned operations via the touch-screen operator's panel.

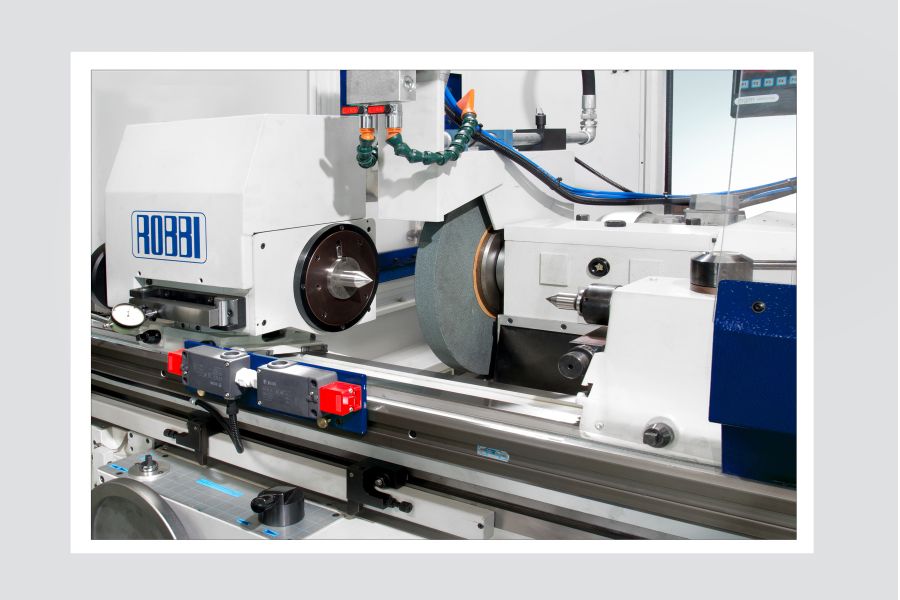

Conventional Cylindrical Grinders

Flexible with top precision levels and an automatic zero stop, these conventional machines allow for fast setup times and are ideal for processing components with tight tolerances. These study and stable machines have a machine bed in normalized cast iron and have a grinding wheel spindle mounted on solid bronze brushes.

- Main handwheel with a division of .01 mm on the diameter

- Micrometric handwheel with a division of 0.001 mm on the diameter

These machines also include the following systems

- 2 axis digital readout (SPACE 2000)

- For wheelhead micropositioning: Incremental linear encoder

- For table micropositioning: Incremental linear encoder

The touch screen panel settings allow for workhead and wheelhead speeds, some parameters of the automatic cycle including dwell time at the reverse and the number of spark-out passes.

General Information

-

Machine Types

Conventional, Semi-Automatic, & CNC

-

Models

All: R & E

Semi & CNC: P & M -

Max Weight on Centers

120 - 4,000 KG

265 - 8,819 lbs -

Max. Grinding Length

600 mm - 8,000 mm

2 ft - 26.25 ft -

Manufacturer

The Robbi Group

Universal Grinding Machine Components

About The Robbi Group

Robbi is an industrial machine manufacturer based out of Italy and since 1936. Robbi uses materials and high-quality components to deliver the utmost precision. Most of their mechanical components are created in their machine shop.

Their company mission is to design and manufacture precision machine tools, technologically advanced, reliable, safe, easy to use, and “tailor-made” for each customer.

Machine Model Technical Comparison Chart

| Model | Max Weight on Centers | Max Grinding Length | |

|---|---|---|---|

R | 120 KG | 600 mm - 1,000 mm |

|

E | 250 KG | 600 mm - 1,000 mm |

|

P | 1,200 KG | 1,150 mm - 3,150 mm | |

M | 4,000 KG | 3,000 mm - 8,000 mm |

Video Gallery — Cylindrical Grinding Machines In Action

Trane Machine Install — Omicron 3000 GE T7

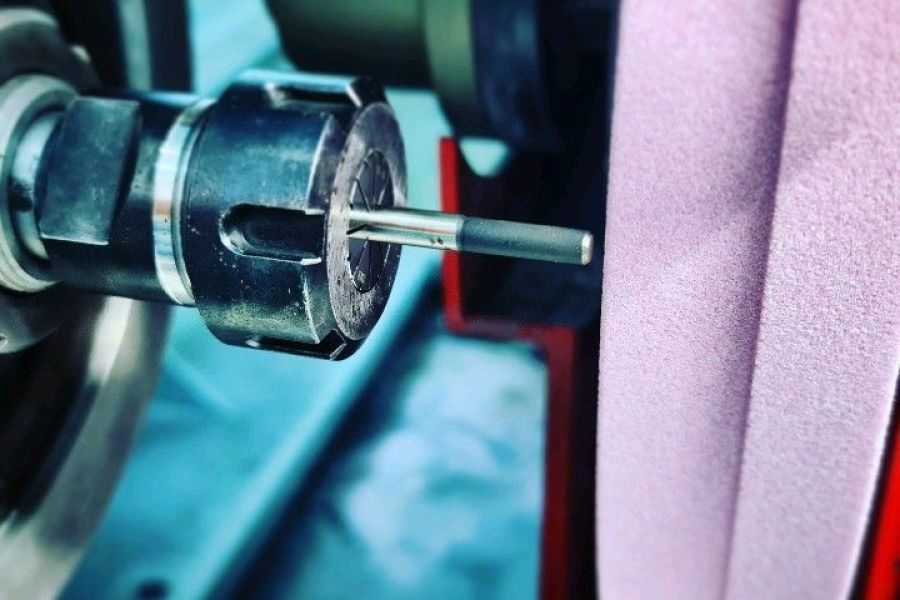

Robbi Diamond Wheel Install Procedures

Riten Industries Machine Install — Omicron 1000 E

Robbi Grinding Wheel Removal Procedures