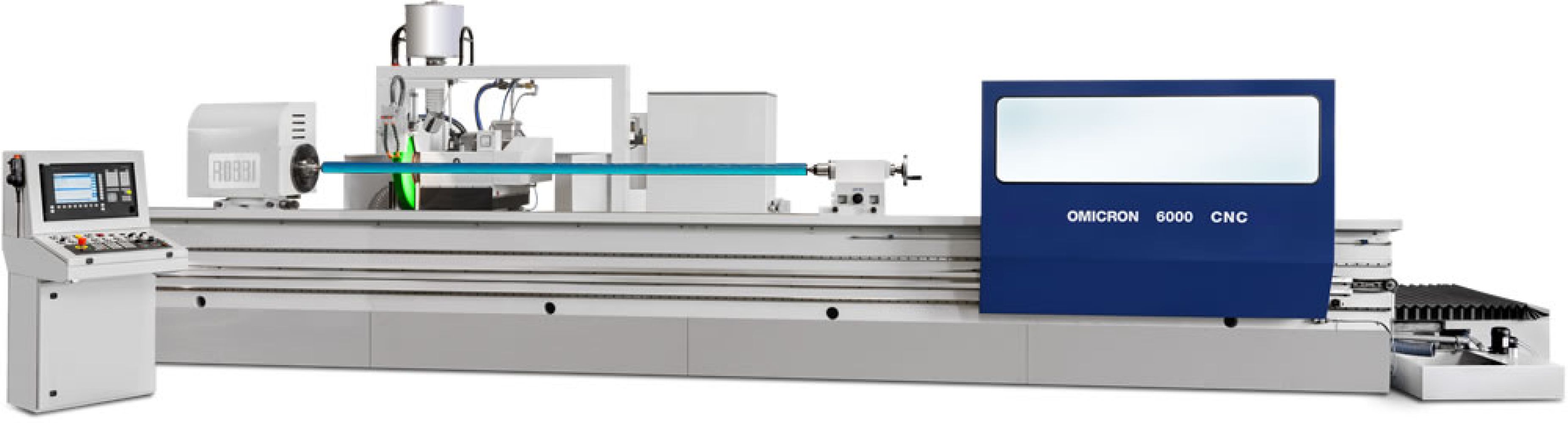

Our MSG CNC series of roll grinding machines are ideally suited to the grinding of carbon fiber, rubber, ceramic, composite, and ferrous alloy rolls.

The following are some of the competitive advantages of grinding machines in the roller machining industry:

- Grinding speed

- An increased amount of material removal

- Superior surface finish and increased part accuracy

Some manufacturers offer a standard lathe with a grinding toolpost; however, this setup has various disadvantages, including a sluggish and inaccurate procedure in an age when engineers expect better surface finishes and part precision.

A Robbi moving wheelhead grinding machine can increase output and replace many lathes, saving money on labor, floor space, and energy. Furthermore, you will notice a higher-quality final component while consuming less electricity.

Mechanical Precision

Base

The rigid machine base structure is manufactured from normalized cast iron. A stabilized process ensures the guides will not deform over the life of the machine.

Wheelhead Carriage

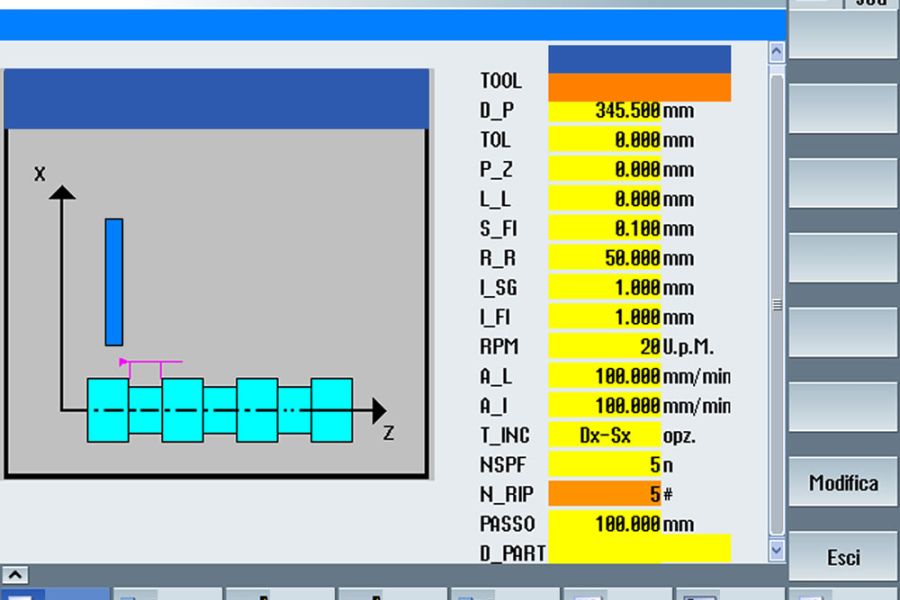

The wheelhead carriage is manufactured from normalized cast iron and designed to dampen any grinding vibration and provide optimal rigidity for increased surface finish.

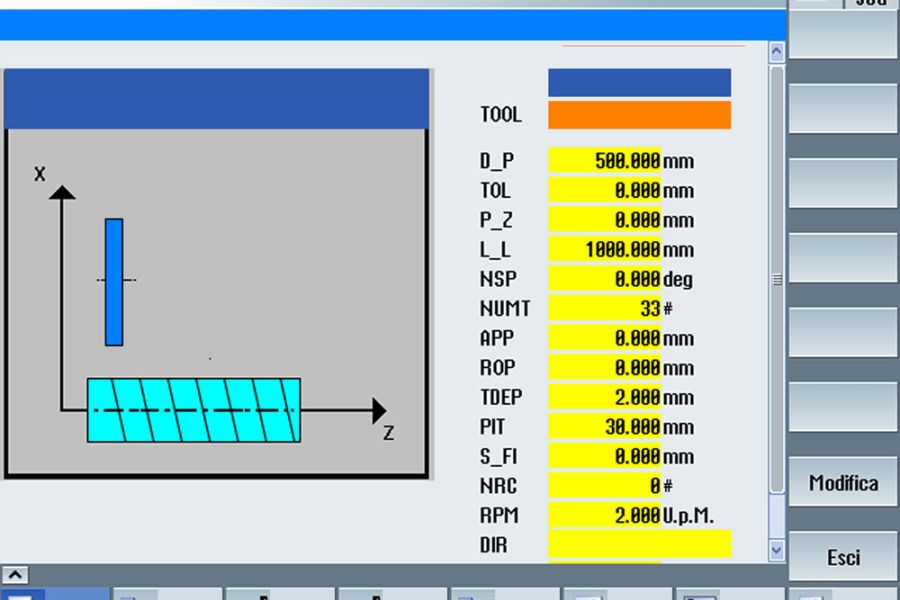

The finished ground face of the wheelhead, is equipped with two high precision, linear guide rails to which 5 pairs of linear guide roller bearings ensure the maximum precision and rigidity of the carriage over the longitudinal travel (Z-axis). The axis travel is carried out via a rack and pinion transmission.

In the transverse axis (X-axis), the carriage runs on linear guide rails with roller guide bearings, and travel is controlled by a ballscrew with a 0.1µ, closed-loop linear encoder.

High precision, linear roller bearings, and guide rails provide minimal friction between moving parts, especially at lower feed rates. Optimal linear machine motion across the full machine axes travels.

Wheelhead

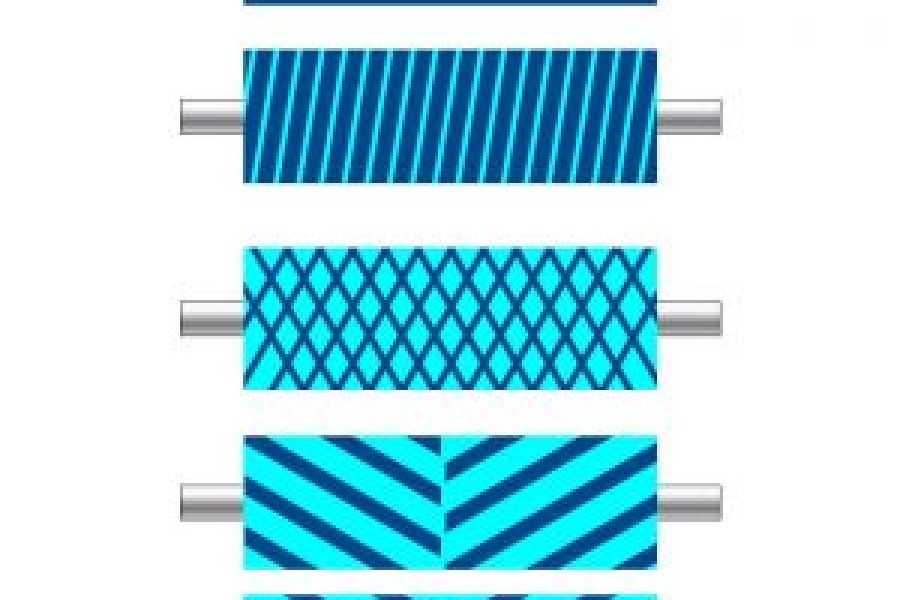

Wheelhead grinders are designed for high efficiency and accuracy grinding applications.

The external grinding wheelhead hydrodynamic spindle rotates on anti-friction metal bushes ensuring a high precision surface finish.

Wheel head rotation is undertaken manually, and on request. Automatic wheelhead rotation is available.

Workhead

A normalized, stabilized cast iron workhead is equipped with high precision spindle bearings providing maximum rigidity and high performance. The workhead can easily be locked for grinding between dead centres.

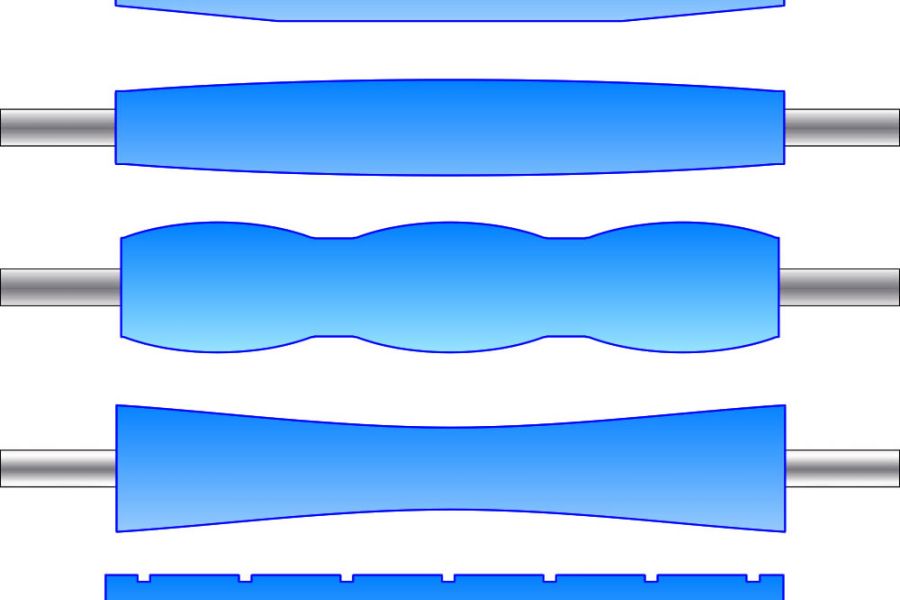

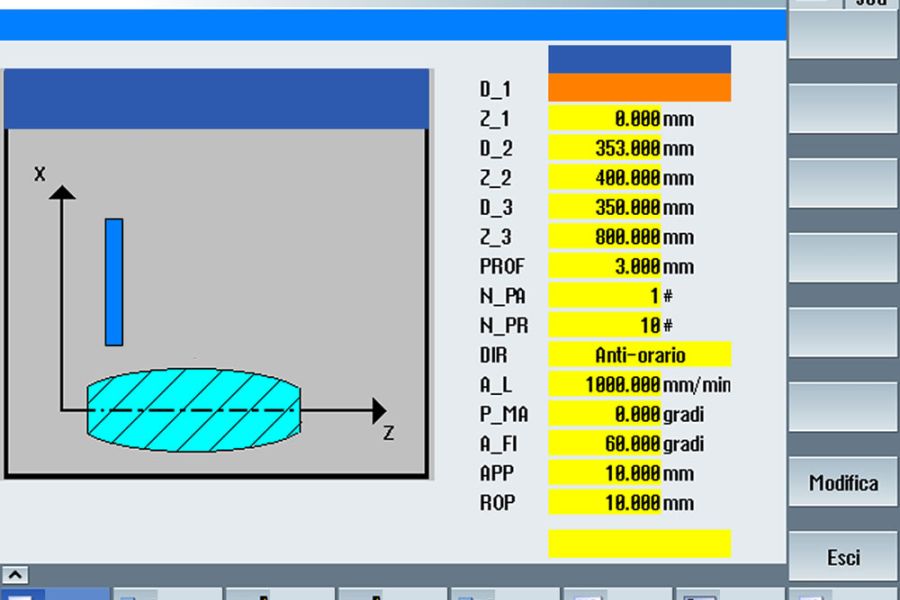

On request, the workhead rotation can be controlled with a C Axis to allow the grinding of grooves.

Omicron MSG 60

Omicron MSG 80

General Information

-

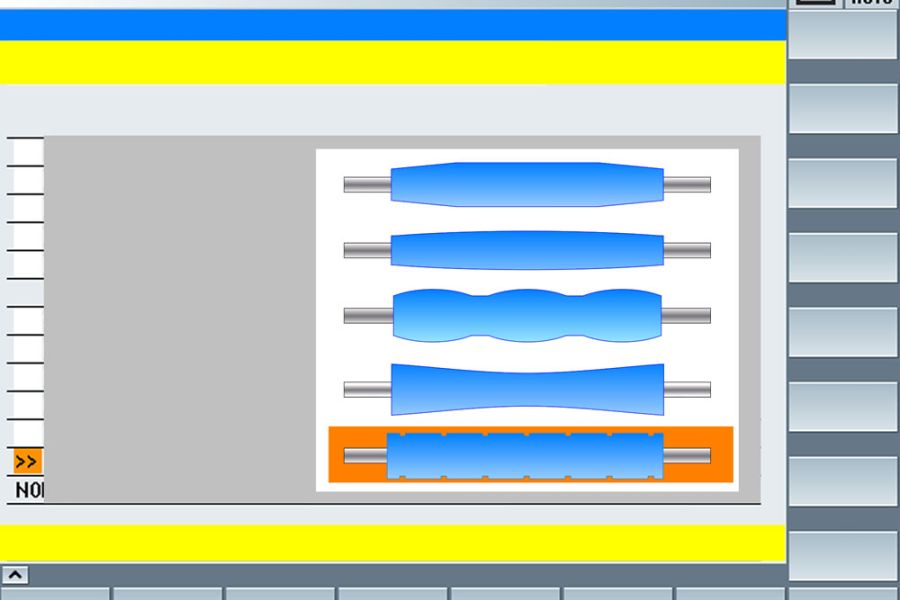

Machine Types

CNC

-

Models

MSG 60 & 80

-

Maximum Lengths

3–4-5-6–7-8-9 e 10 meters -

Maximum Diameter

695 mm - 995 mm

-

Maximum Weight

2000 kg - 8000 kg

About The Robbi Group

Robbi is an industrial machine manufacturer based out of Italy and since 1936. Robbi uses materials and high-quality components to deliver the utmost precision. Most of their mechanical components are created in their machine shop.

Their company mission is to design and manufacture precision machine tools, technologically advanced, reliable, safe, easy to use, and “tailor-made” for each customer.

Machine Model Technical Comparison Chart

In the Omicron range there are 2 product Moving wheelhead lines, the MSG 60 and the MSG 80, whose main features can be summarized by the following table.

| Model | Maximum Diameter | Maximum Weight |

|---|---|---|

Omicron MSG 60 | 695 mm | 2000 kg |

Omicron MSG 80 | 995 mm | 8000 kg |