- die-

makers - mechanic workshops

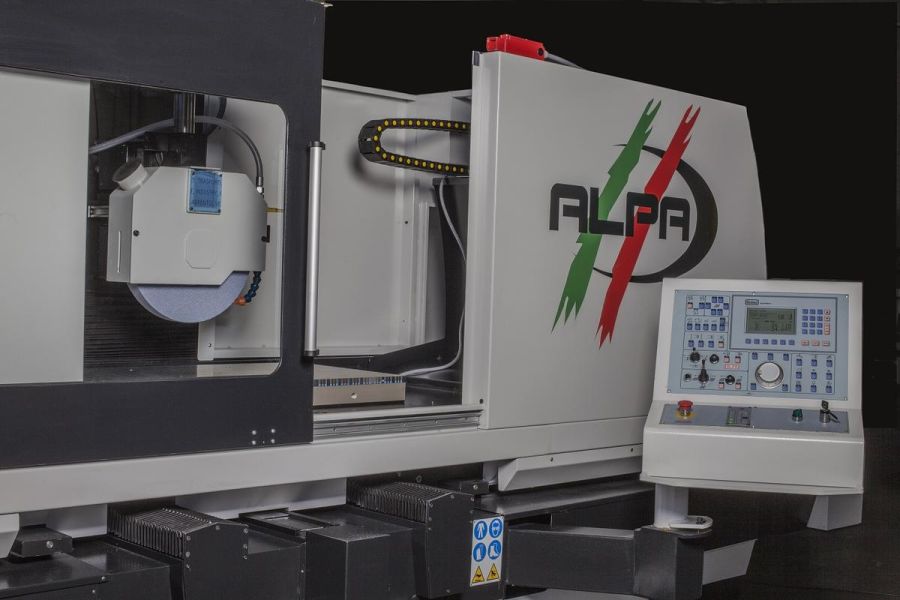

An industrial surface grinder is a machine that you use for smooth finishes on flat surfaces. This commonly used machining system cuts metallic and non-metallic materials with a grinding wheel, leaving a flat and sometimes smooth surface behind.

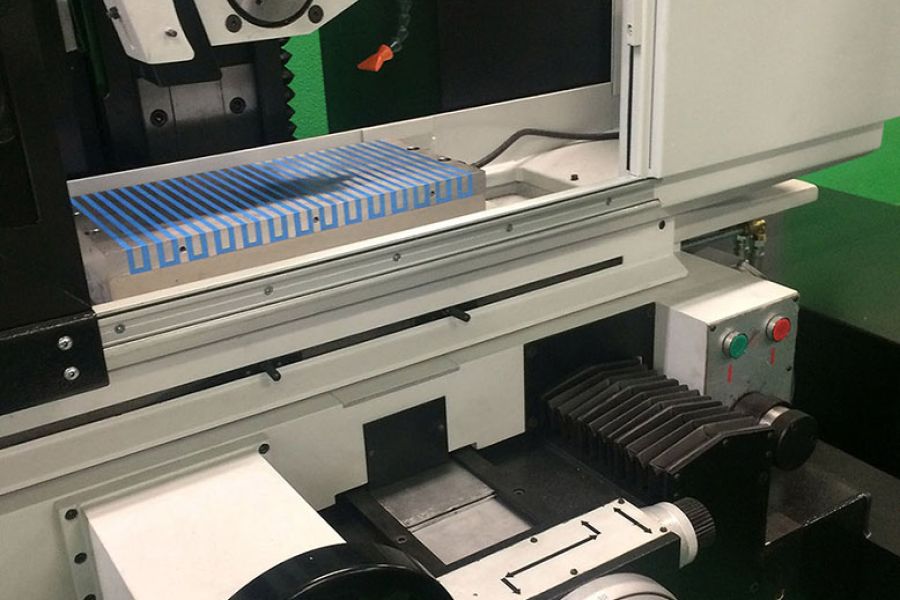

To effectively flatten and smooth metal, Alpa's precise grinding wheels are covered with abrasive particles. The maximum grinding width on our "ALPAGrind" surface grinder line ranges from 6.00" to 27.55". The length of the material varies from 16" to 82.67".

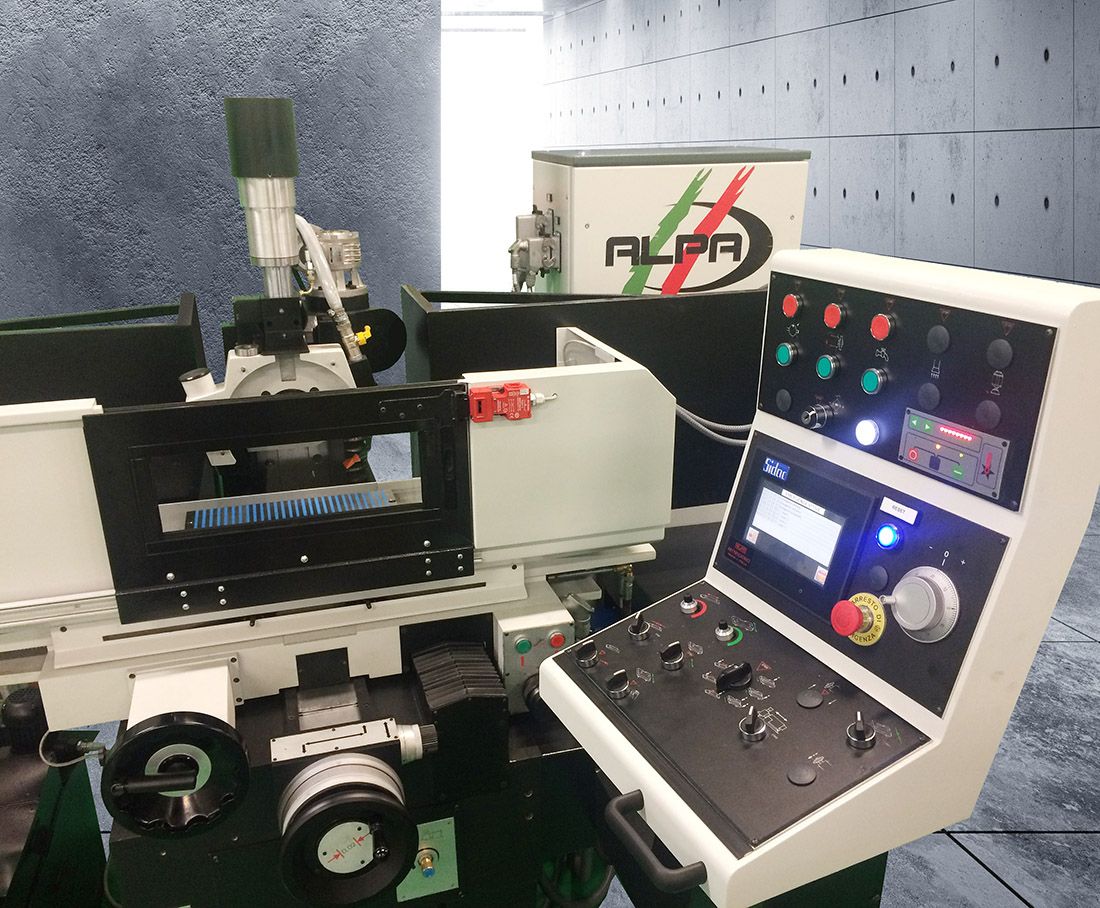

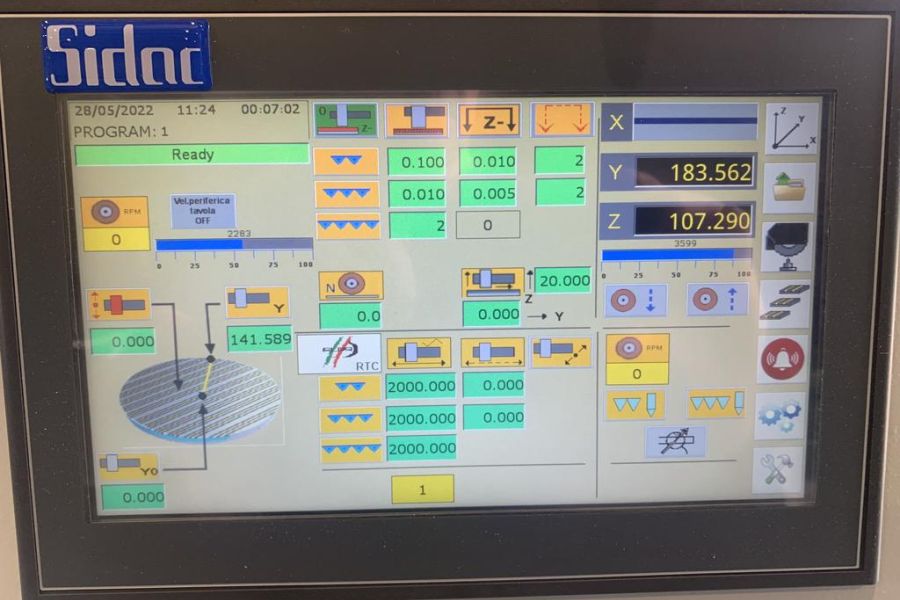

On our surface grinders, we provide CNC (Computer-assisted), semi-automatic (PLC), and manual control options. A moving column and a user-friendly touchscreen operation panel are included in our program-controlled surface grinder. A servomotor drives the automatic down feed.

A feed counter, optional feed types, a hand-fed electromagnetic hand wheel, and the ability to alter the disk suction size are all set using the physical control panel. The axis feed size, grinding precision, number of feeds, disk suction size, and grinding distance are all displayed on the digital touchscreen panel.

Universal Optional Add-Ons

- Electronic dynamic balancing

- Variable-speed inverter

- Paper Filtration system

- Electro magnetic chuck brass with control unit

RT Base Series

The Alpa RT Base series of surface grinders are designed for both precision and production grinding applications.

The RT 450 excels in toolroom and small batch production environments, while the RT 550 caters to high-volume production grinding while still maintaining accuracy.

Both models prioritize user-friendliness and can be outfitted with various accessories to suit specific needs.

Target End Users For Both Machines

- toolmakers

- precision mechanics

- hard metal works

- profile grinding

- production of small pieces

The RT 550 is also suitable for the following applications.

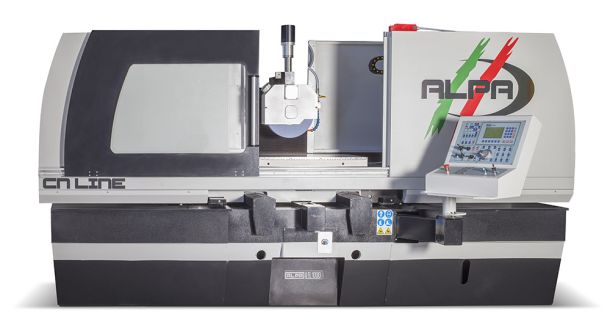

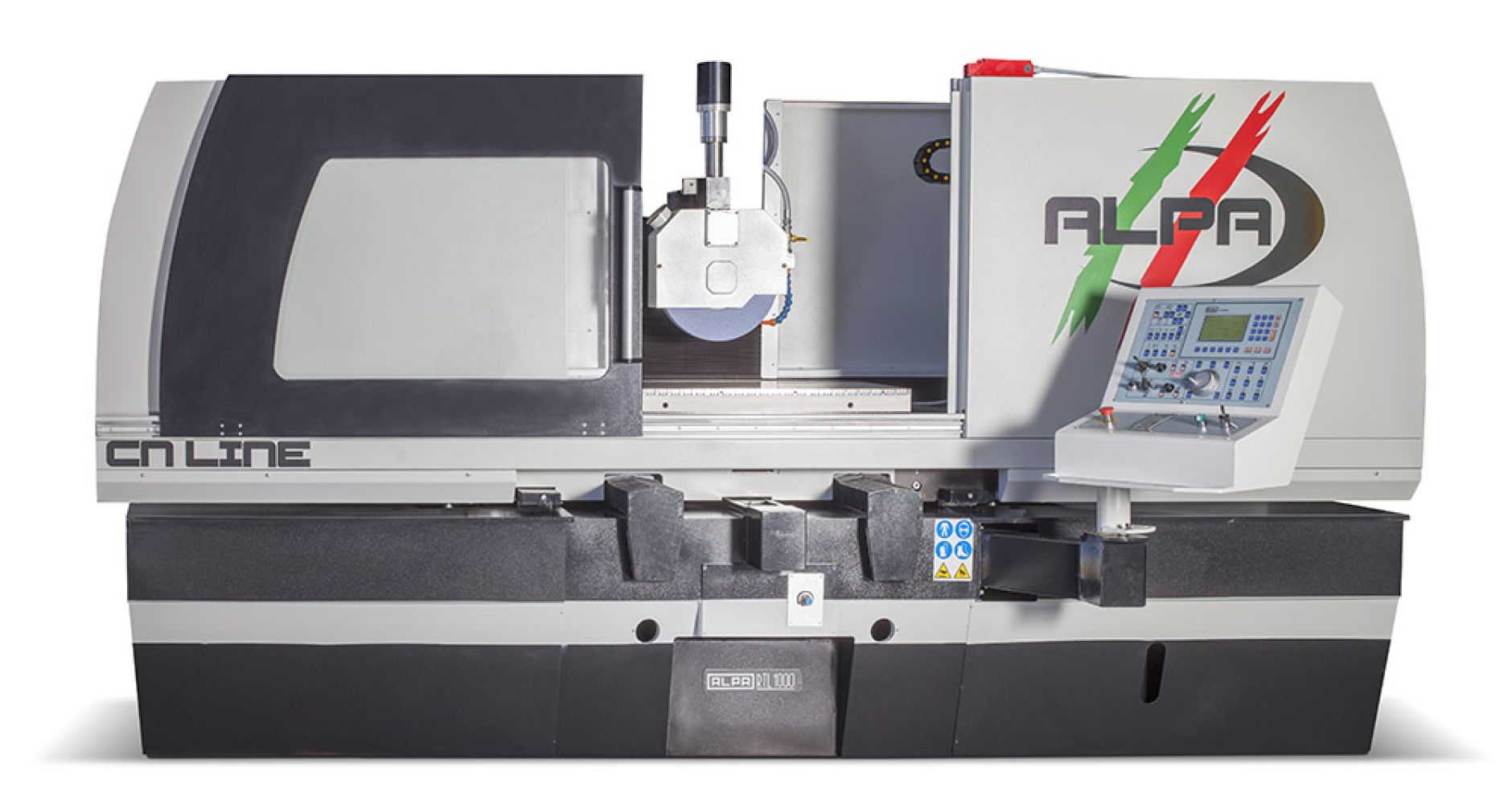

RT Pro & RTL Series

The RT Surface Grinders are the most popular because of the decades of experience, research, and development that have preceded these particular machines.

Features

- Hydrolift to cross slideaways

- External location of the hydraulic and electric unit

- Wheelhead traversing system arranged for rigidity and absolute sensitivity

- Automatic longitudinal traverse of table, cross slide traverse, and downfeed wheelhead

- For better stability, cross slide equipped with two more flat slideaways with hydrolift.

Note: RT 1000 and RTL 1000 differ from RT 700 and RTL 700 for table length.

Ideal Applications

These machines are great for producing small pieces and for the toolroom of high precision machining.

- Machine tools manufacturers

- Profile grinding

- Precision mechanics

- Production of medium size parts

Optional Additions

- Wheel turning and forming devices

- Vertical grinding attachments

- Swaft separators

- Magnetic chuck

- Automatic cycle attachments

RV Series

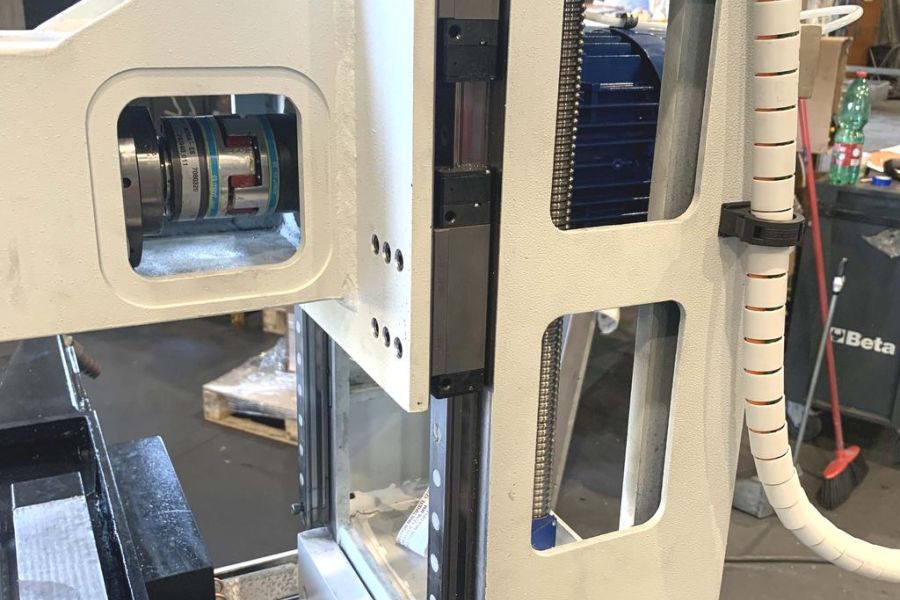

Our RV series surface grinders include a double-column structure and the base and fixed column are made of a single casting. The movable column pivots on the base via big precision bearings. The upper part with support operates in an oil bath.

Special self-adjusting bearings allow the spindle to rotate. The vertical fine feed is achieved through a sensitive drum, graduated in 0.01 mm.

RVB 300

- Equipped with rectangular table

RVC 250

- Incorporates rotary chuck

Standard Additions

- Cast iron base

- Coolant system

RVB 300 Optional Addition

- To obtain 150 mm cross traverse, an additional table can be provided with the RVB 300.

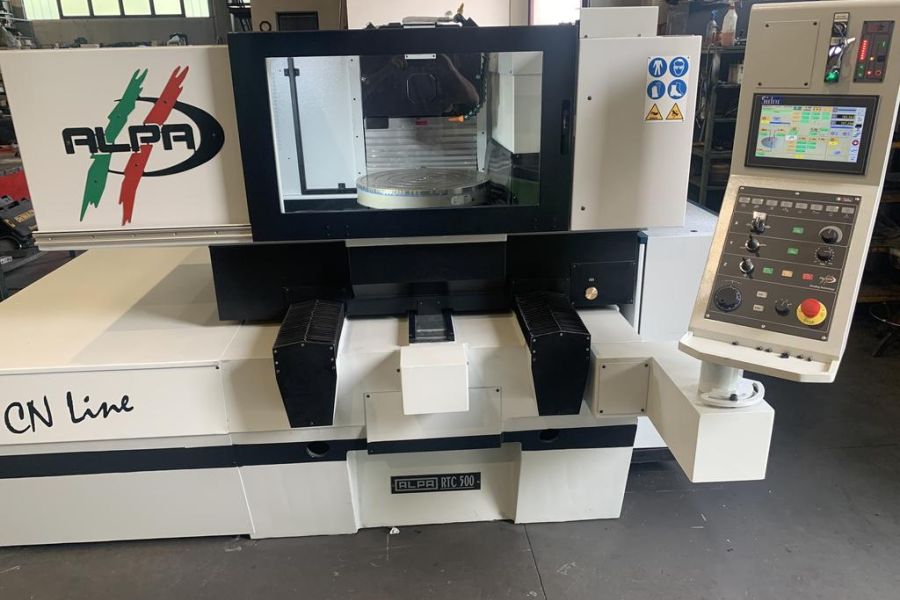

RTC Series

This model is best used for ring grinding and the fast accurate production of small components in batches as it's designed for maximum output within close limits of parallelism, flatness, and surface finish.

Optimum table speed adjustments automatically varied progressively as the cross slide moves towards and away from the grinding wheel. Revolutions per minute will remain constant from the edge of the rotary table to its centre producing mirror-finished surfaces.

RTCI Distinction

The RTCI model is unique as a rotary chuck, which can be tilted ± 10° forward or toward the upright for the accurate resharpening of saw cutting edges, cutters, and other similar tools.

Standard Additions

- Automatic downfeed of wheelhead applied at every cross slide reversal

- Table speed controller via static electronic equipment controls

Optional Additions

- Headmounted straight wheel forming attachment

- Power rise and fall to wheelhead

- Wet grinding equipment

- Electromagnetic and permanent magnetic chucks (500 mm and 700 mm in diameter)

- Automatic grinding cycle equipment

- Electronic dial gauge

RTM Series

These heavy-duty hydraulically operated production grinders are for grinding large press tools and dies. The heavy cuts don't compromise accuracy and are also ideal for robust construction projects. Designed for maximum output and precision, these machines leverage a large wheel size and wheel motor power.

Standard Options

- Hydraulically operated longitudinal traverse

- Electro-mechanical cross traverse

- Automatic downfeed of wheelhead

- Wet grinding attachment

Optional Additions

- Raised column (for obtaining a 28″ grinding height)

- Swiveling vertical grinding attachments

- Wheel truing and forming devices

- Swarf separators

- Magnetic chucks

- Automatic cycle attachments

General Information

-

Machine Types

Conventional, Semi-Automatic, & CNC

-

Models

RT, RTL, RVB, RVC, RTC, RTM

-

Table Dimensions

- RT450 = 450x200 mm

- RT550 = 550x300 mm

- RT700 = 700x300 mm

- RT1000 = 1000x300 mm

- RTL700 = 700x500 mm

- RTL1000 = 1000x500 mm

- RVB300 = 400x150 mm

-

Manufacturer

Alpa Grinding Technology

About Alpa Grinding Technology

ALPA has been manufacturing horizontal spindle surface grinding equipment for the Italian and international markets since 1953. Experience in the field, an in-depth analysis of grinding structures, and a support desk at the highest professional levels are the foundations of ALPA's machines' performance.

Each grinding series features a cast iron frame with larger dimensions for precision and rigidity, as well as hydrostatic guiding rails and hand-scraped surfaces. ALPA is able to provide its customers with a wide selection of grinding machines, ranging from the smallest 450/200 to the largest 2000/700, all while being attentive to market needs.

Why Choose Alpa?

-

Exceptional Structural Rigidity

-

Advanced Software Development

-

After-Sales Assistance

Ditch the Code, Embrace the Speed: How ALPA System Touch Makes You a CNC Programming Mastermind

Surface Grinding Machine Model Technical Comparison Chart

| Model | Max. Cross Traverse | Max. Grinding Length |

|---|---|---|

RT 450 | 220mm | 450mm |

RT 550 | 340mm | 550mm |

RT 700 | 350mm | 700mm |

RT 1000 | 350mm | 1000mm |

RTL 700 | 560mm | 700mm |

RTL 1000 | 560mm | 1000mm |

RVB 300 | 350mm | |

RTC 300 | 400mm | |

RTC 500 | 600mm | |

RTC 750 | 850mm | |

RTC 1000 | 1150mm | |

RTM 1200 | 800mm | 1,200mm |

RTM 1600 | 800mm | 1,600mm |

RTM 2100 | 800mm | 2,100mm |